DADA SOM/DADA Hardware/pdf

General Information[edit | edit source]

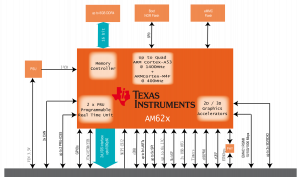

DADA Block Diagram[edit | edit source]

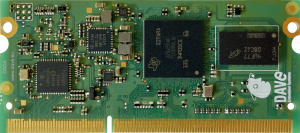

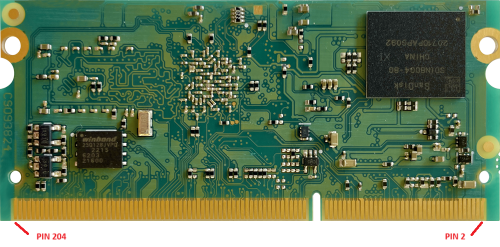

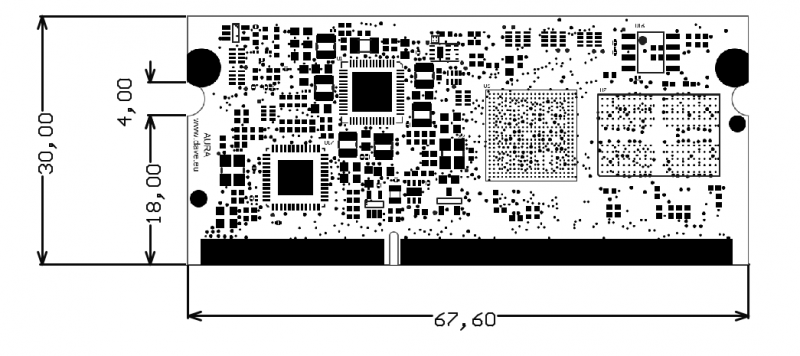

DADA TOP View[edit | edit source]

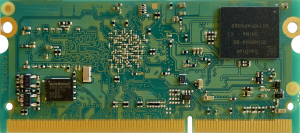

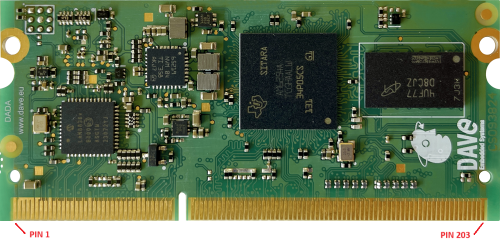

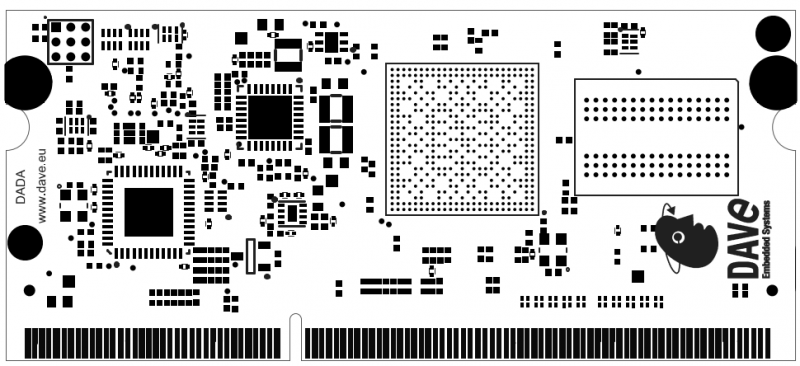

DADA BOTTOM View[edit | edit source]

Processor and memory subsystem[edit | edit source]

The heart of DADA module is composed by the following components:

- AM62x SoC application processor

- Power supply unit

- DDR4 memory bank

- eMMC storage device

- Connectors:

- 1 x 204 pins SO-DIMM edge connector with interfaces signals

- partially compatible with AXEL Lite SOM

- 1 x 204 pins SO-DIMM edge connector with interfaces signals

This chapter shortly describes the main DADA components.

Processor Info[edit | edit source]

| Processor | AM62x SingleCore | AM62x DualCore | AM62x Quadcore |

| # Cores | 1x Arm® Cortex®-A53

1x Arm® Cortex®-M4F |

2x Arm® Cortex®-A53

1x Arm® Cortex®-M4F |

4x Arm® Cortex®-A53

1x Arm® Cortex®-M4F |

| Clock | Core: 1.4 GHz (Industrial)

Cortex-M4F: up to 400 MHz | ||

| L2

Cache |

512KB MB | ||

| DDR4 | 16 bit

(1600MT/s) | ||

| GPU | 3D: PowerVR AXE-1-16M

OpenGL ES 3.1 | ||

| PRUSS | Dual core Programmable Real-Time Unit Subystem

up to 333 MHz | ||

| Display

Controller |

Dual independent LVDS channel

2x 1920x1080@60 or 1x 2048x1080 + 1x 1280x720 | ||

| Video

Output |

Dual LVDS channel 24-bit RGB DPI | ||

| Camera

Input |

1x MIPI CSI (4-lanes) | ||

| Ethernet | 2x 10/100/1000 Mbit/s controller with TSN and IEEE1588 | ||

| USB | 2x USB 2.0 Host or Device DRD (Dual-Role Device) | ||

RAM memory bank[edit | edit source]

LPDD4 SDRAM memory bank is composed by 1x16-bit width chip. The following table reports the SDRAM specifications:

| CPU connection | DDR subsystem (DDRSS) |

| Size max | 8 GB |

| Width | 16 bit |

| Speed | 1600 MHz |

eMMC storage[edit | edit source]

On board main storage memory eMMC is connected to the MMC0 interface and it can act as boot peripheral. The following table reports the eMMC flash specifications:

| CPU connection | MMC0 |

| Size min | 8 GB |

| Size max | 64 GB |

| Bootable | Yes |

NOR QSPI flash[edit | edit source]

Alternative option for main storage memory can be a serial NOR flash connected to the CPU's Quad serial flash controller. It can act as boot peripheral. The following table reports the NOR flash specifications:

| CPU connection | SPI Serial flash controller |

| Size | 16GB |

| Width | 1,4 bit mode |

| Bootable | Yes |

Memory map[edit | edit source]

For detailed information, please refer to chapter 9.1 “Memory Controllers” of the AM62x Processor Technical Reference Manual

Power supply unit[edit | edit source]

DADA embeds all the elements required for powering the unit, therefore power sequencing is self-contained and simplified. Nevertheless, power must be provided from carrier board, and therefore users should be aware of the ranges power supply can assume as well as all other parameters.

Hardware versioning and tracking[edit | edit source]

DAD SOM implements well established versioning and tracking mechanisms:

- PCB version is copper printed on PCB itself, as shown in Fig. 1

- serial number: it is printed on a white label, as shown in Fig. 2: see also Product serial number page for more details

- ConfigID: it is used by software running on the board for the identification of the product model/hardware configuration. For more details, please refer to this link

- on DADA SOM ConfigID is stored in (TBD)

Part number composition[edit | edit source]

DADA SOM module part number is identified by the following digit-code table:

| Part number structure | Options | Description |

|---|---|---|

| Family | DSAA | Family prefix code |

| SOC |

|

Other versions can be available, please contact technical support |

| RAM |

|

|

| Storage |

|

|

| Boot mode |

|

|

| Mounting options |

|

|

| RFU |

|

Reserved for Future Use |

| Temperature range |

|

|

| PCB revision |

|

PCB release may change for manufacturing purposes (i.e. text fixture adaptation) |

| Manufacturing option |

|

typically connected to production process and quality |

| Software Configuration | -00: standard factory u-boot pre-programmed | If customers require custom SW deployed this section should be defined and agreed. Please contact technical support |

Example[edit | edit source]

DADA SOM code DSAAA13100I0R-00

- DSAA - DADA

- A - Texas Instruments AM6254ATCGHAALW Arm A53 QuadCore, PRU, GPU @1.4GHz

- 1 - 2GB DDR4

- 3 - 8GB eMMC

- 1 - Boot from on board eMMC

- 0 - 3.3V high performance PMIC

- 0 - RFU

- I - Industrial grade: -40 to 85°C

- 0 - first version

- R - RoHS

- -00 - standard factory u-boot pre-programmed

Pinout Table[edit | edit source]

Connector and Pinout Table[edit | edit source]

Connector description[edit | edit source]

In the following table are described all available connector integrated on DADA:

| Connector name | Connector Type | Notes | Carrier board counterpart |

|---|---|---|---|

| J1 | SODIMM DDR3 edge connector 204 pin | TE Connectivity 2-2013289-1 |

The dedicated carrier board must mount the mating connector and connect the desired peripheral interfaces according to DADA pinout specifications. See the images below for reference:

Pinout table naming conventions[edit | edit source]

This chapter contains the pinout description of the DADA module, grouped in two tables (odd and even pins) that report the pin mapping of the 204-pin SO-DIMM DADA connector.

Each row in the pinout tables contains the following information:

| Pin | Reference to the connector J1 pin |

| Pin type | Pin topolgy according to Unica Industrial Dave standard:

|

| UNICA pin name | Pin name according to Unica Industrial Dave standard |

| Type | Electrical pin type:

|

| DADA pin name | Pin (signal) name on the DADA J1 connector.

In bold if it covers a UNICA pinout feature. |

| Internal connections |

Connections to the DADA components:

|

| Ball/pin # | Component ball/pin number connected to signal |

| SoM voltage domain | I/O voltage levels (SoM main rails) |

| SoC voltage domain | I/O voltage levels (all voltage rails) |

| Notes | Remarks on special pin characteristics |

| Pin MUX mode | Muxes:

In bold the mux applied in the standard device-tree to cover a UNICA pinout functionality. |

SoM voltage domains[edit | edit source]

| Voltage domain | Nominal voltage | Source | Peripheral PWR | Notes |

|---|---|---|---|---|

| VIN_SOM | 3.3 V | External | SoM input PWR | See Operational_characteristics of the SoM wiki page |

| VDD_3V3 | 3.3 V | Internal | IO | Voltage generated by the internal PSU. |

| VDD_1V8 | 1.8 V | Internal | IO | Voltage generated by the internal PSU. |

| VDD_RGMII | 3.3 V | Internal | RGMII | It can be set to 1.8 V with HW mounting option. |

| MMC2_POWER | 1.8 V o 3.3 V | External | MMC2 | Voltage generated by the carrier board PSU, synchronous with SOM_PGOOD signal. |

For more details and recommended power-up sequence see Power Supply Unit (PSU) wiki page.

Pinout choice[edit | edit source]

It is not possible to bring all the SoC pins to the J1 connector. The mapping choice was made in order to respect:

- cover always-present and variable peripherals mapped in the Unica Industrial Dave standard pinout

- bring out all SoC peripherals of the MCU, CANUART and PRU domain

- bring out all pins with BOOTMODE function

Pinout table XLS file[edit | edit source]

For your convenience, please find a spreadsheet with:

Pinout Table ODD pins declaration[edit | edit source]

| Pin | Pin Type | UNICA pin name | Type | DADA pin name | Internal Connections | Ball/pin # | SoM Voltage domain | SoC Voltage domain | Notes | Boot Mode | Alternative mux modes | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| J2.1 | AP | DGND | G | DGND | |||||||||

| J2.3 | AP | VIN_SOM | PWR | VIN_SOM | VIN_SOM | ||||||||

| J2.5 | AP | VIN_SOM | PWR | VIN_SOM | VIN_SOM | ||||||||

| J2.7 | AP | VIN_SOM | PWR | VIN_SOM | VIN_SOM | ||||||||

| J2.9 | AP | VIN_SOM | PWR | VIN_SOM | VIN_SOM | ||||||||

| J2.11 | AP | DGND | G | DGND | |||||||||

| J2.13 | AP | ETH_A_LED1 | S | O | ETH1_LED1 | LAN | 18 | VDD_3V3 | |||||

| J2.15 | AP | ETH_A_LED2 | S | O | ETH1_LED2 | LAN | 16 | VDD_3V3 | |||||

| J2.17 | AP | DGND | G | DGND | |||||||||

| J2.19 | AP | ETH_A_TXRX0_P | D | IO | ETH1_TXRX0_P | LAN | 2 | VDD_3V3 | |||||

| J2.21 | AP | ETH_A_TXRX0_N | D | IO | ETH1_TXRX0_N | LAN | 3 | VDD_3V3 | |||||

| J2.23 | AP | ETH_A_TXRX1_P | D | IO | ETH1_TXRX1_P | LAN | 5 | VDD_3V3 | |||||

| J2.25 | AP | ETH_A_TXRX1_N | D | IO | ETH1_TXRX1_N | LAN | 6 | VDD_3V3 | |||||

| J2.27 | AP | ETH_A_TXRX2_P | D | IO | ETH1_TXRX2_P | LAN | 7 | VDD_3V3 | |||||

| J2.29 | AP | ETH_A_TXRX2_N | D | IO | ETH1_TXRX2_N | LAN | 8 | VDD_3V3 | |||||

| J2.31 | AP | ETH_A_TXRX3_P | D | IO | ETH1_TXRX3_P | LAN | 10 | VDD_3V3 | |||||

| J2.33 | AP | ETH_A_TXRX3_N | D | IO | ETH1_TXRX3_N | LAN | 11 | VDD_3V3 | |||||

| J2.35 | AP | DGND | G | DGND | |||||||||

| J2.37 | VAR | VAR_A_37 | S | IO | GPMC0_WP# | SoC | K25 | VDD_3V3 | VDDSHV3 | ALT-0 | GPMC0_WP# | ||

| ALT-1 | AUDIO_EXT_REFCLK1 | ||||||||||||

| ALT-2 | GPMC0_A22 | ||||||||||||

| ALT-3 | UART6_TXD | ||||||||||||

| ALT-4 | PR0_PRU0_GPO15 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI15 | ||||||||||||

| ALT-6 | TRC_DATA13 | ||||||||||||

| ALT-7 | GPIO0_39 | ||||||||||||

| J2.37 | VAR | VAR_A_37 (*) | S | O | ETH1_LED3 | LAN | 15 | VDD_3V3 | Hardware mounting option (*) | ||||

| J2.39 | VAR | VAR_A_39 | S | IO | GPMC0_DIR | SoC | M22 | VDD_3V3 | VDDSHV3 | ALT-0 | GPMC0_DIR | ||

| ALT-1 | PR0_ECAP0_IN_APWM_OUT | ||||||||||||

| ALT-3 | MCASP2_AXR13 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO16 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI16 | ||||||||||||

| ALT-6 | TRC_DATA14 | ||||||||||||

| ALT-7 | GPIO0_40 | ||||||||||||

| ALT-8 | EQEP2_S | ||||||||||||

| J2.39 | VAR | VAR_A_39 (*) | S | O | ETH1_LED4 | LAN | 14 | VDD_3V3 | Hardware mounting option (*) | ||||

| J2.39 | VAR | VAR_A_39 (*) | S | O | ETH1_LED5 | LAN | 13 | VDD_3V3 | Hardware mounting option (*) | ||||

| J2.41 | VAR | VAR_A_41 | S | IO | GPMC0_AD03 | SoC | N25 | VDD_3V3 | VDDSHV3 | BOOTMODE03 | ALT-0 | GPMC0_AD3 | |

| ALT-1 | PR0_PRU1_GPO11 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI11 | ||||||||||||

| ALT-3 | MCASP2_AXR7 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO3 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI3 | ||||||||||||

| ALT-6 | TRC_DATA1 | ||||||||||||

| ALT-7 | GPIO0_18 | ||||||||||||

| J2.43 | VAR | VAR_A_43 | S | IO | MCU_UART0_TXD | SoC | A5 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_UART0_TXD | ||

| ALT-7 | MCU_GPIO0_6 | ||||||||||||

| J2.45 | VAR | VAR_A_45 | S | IO | MCU_UART0_RXD | SoC | B5 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_UART0_RXD | ||

| ALT-7 | MCU_GPIO0_5 | ||||||||||||

| J2.47 | VAR | UART_B_TX | S | IO | VOUT_DATA5 | SoC | Y24 | VDD_3V3 | VDDSHV3 | ALT-0 | VOUT0_DATA5 | ||

| ALT-1 | GPMC0_A5 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO5 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI5 | ||||||||||||

| ALT-4 | UART4_TXD | ||||||||||||

| ALT-5 | PR0_PRU0_GPO13 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI13 | ||||||||||||

| ALT-7 | GPIO0_50 | ||||||||||||

| J2.49 | VAR | UART_B_RX | S | IO | VOUT_DATA4 | SoC | Y25 | VDD_3V3 | VDDSHV3 | ALT-0 | VOUT0_DATA4 | ||

| ALT-1 | GPMC0_A4 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO4 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI4 | ||||||||||||

| ALT-4 | UART4_RXD | ||||||||||||

| ALT-5 | PR0_PRU0_GPO12 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI12 | ||||||||||||

| ALT-7 | GPIO0_49 | ||||||||||||

| J2.51 | VAR | UART_B_RTS | S | IO | VOUT_DATA14 | SoC | Y22 | VDD_3V3 | VDDSHV3 | ALT-0 | VOUT0_DATA14 | ||

| ALT-1 | GPMC0_A14 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO13 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI13 | ||||||||||||

| ALT-4 | UART4_RTSn | ||||||||||||

| ALT-5 | PR0_PRU0_GPO4 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI4 | ||||||||||||

| ALT-7 | GPIO0_59 | ||||||||||||

| J2.53 | VAR | UART_B_CTS | S | IO | VOUT_DATA15 | SoC | AA21 | VDD_3V3 | VDDSHV3 | ALT-0 | VOUT0_DATA15 | ||

| ALT-1 | GPMC0_A15 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO14 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI14 | ||||||||||||

| ALT-4 | UART4_CTSn | ||||||||||||

| ALT-5 | PR0_PRU0_GPO5 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI5 | ||||||||||||

| ALT-7 | GPIO0_60 | ||||||||||||

| J2.55 | VAR | VAR_A_55 | S | IO | PMIC_INT | SoC | M24 | VDD_3V3 | VDDSHV3 | Internal 10K pull-up | ALT-0 | GPMC0_BE0_CLE# | |

| ALT-2 | MCASP1_ACLKX | ||||||||||||

| ALT-4 | PR0_PRU0_GPO12 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI12 | ||||||||||||

| ALT-6 | TRC_DATA10 | ||||||||||||

| ALT-7 | GPIO0_35 | ||||||||||||

| J2.57 | AP | DGND | G | DGND | |||||||||

| J2.59 | VAR | SDIO_B_PWR | PWR | MMC2_POWER | SoC | J18 | MMC2_POWER | VDDSHV6 | |||||

| J2.61 | AP | SDIO_B_DATA0 | S | IO | MMC2_DAT0 | SoC | B24 | MMC2_POWER | VDDSHV6 | ALT-0 | MMC2_DAT0 | ||

| ALT-1 | MCASP1_AXR0 | ||||||||||||

| ALT-7 | GPIO0_68 | ||||||||||||

| J2.63 | AP | SDIO_B_DATA1 | S | IO | MMC2_DAT1 | SoC | C25 | MMC2_POWER | VDDSHV6 | ALT-0 | MMC2_DAT1 | ||

| ALT-1 | MCASP1_AXR1 | ||||||||||||

| ALT-7 | GPIO0_67 | ||||||||||||

| J2.65 | AP | SDIO_B_DATA2 | S | IO | MMC2_DAT2 | SoC | E23 | MMC2_POWER | VDDSHV6 | ALT-0 | MMC2_DAT2 | ||

| ALT-1 | MCASP1_AXR2 | ||||||||||||

| ALT-3 | UART5_TXD | ||||||||||||

| ALT-7 | GPIO0_66 | ||||||||||||

| J2.67 | AP | SDIO_B_DATA3 | S | IO | MMC2_DAT3 | SoC | D24 | MMC2_POWER | VDDSHV6 | ALT-0 | MMC2_DAT3 | ||

| ALT-1 | MCASP1_AXR3 | ||||||||||||

| ALT-3 | UART5_RXD | ||||||||||||

| ALT-7 | GPIO0_65 | ||||||||||||

| J2.69 | AP | SDIO_B_CMD | S | IO | MMC2_CMD | SoC | C24 | MMC2_POWER | VDDSHV6 | ALT-0 | MMC2_CMD | ||

| ALT-1 | MCASP1_AFSR | ||||||||||||

| ALT-2 | MCASP1_AXR4 | ||||||||||||

| ALT-3 | UART6_TXD | ||||||||||||

| ALT-7 | GPIO0_70 | ||||||||||||

| J2.71 | AP | SDIO_B_CLK | S | O | MMC2_CLK | SoC | D25 | MMC2_POWER | VDDSHV6 | ALT-0 | MMC2_CLK | ||

| ALT-1 | MCASP1_ACLKR | ||||||||||||

| ALT-2 | MCASP1_AXR5 | ||||||||||||

| ALT-3 | UART6_RXD | ||||||||||||

| ALT-7 | GPIO0_69 | ||||||||||||

| J2.73 | AP | DGND | G | DGND | |||||||||

| J2.75 | AP | SDIO_A_DATA0 | S | IO | MMC1_DAT0 | SoC | A22 | VDD_3V3 | VDDSHV5 | ALT-0 | MMC1_DAT0 | ||

| ALT-1 | CP_GEMAC_CPTS0_HW2TSPUSH | ||||||||||||

| ALT-2 | TIMER_IO3 | ||||||||||||

| ALT-3 | UART2_CTSn | ||||||||||||

| ALT-4 | ECAP2_IN_APWM_OUT | ||||||||||||

| ALT-7 | GPIO1_45 | ||||||||||||

| J2.77 | AP | SDIO_A_DATA1 | S | IO | MMC1_DAT1 | SoC | B21 | VDD_3V3 | VDDSHV5 | ALT-0 | MMC1_DAT1 | ||

| ALT-1 | CP_GEMAC_CPTS0_HW1TSPUSH | ||||||||||||

| ALT-2 | TIMER_IO2 | ||||||||||||

| ALT-3 | UART2_RTSn | ||||||||||||

| ALT-4 | ECAP1_IN_APWM_OUT | ||||||||||||

| ALT-7 | GPIO1_44 | ||||||||||||

| J2.79 | AP | SDIO_A_DATA2 | S | IO | MMC1_DAT2 | SoC | C21 | VDD_3V3 | VDDSHV5 | ALT-0 | MMC1_DAT2 | ||

| ALT-1 | CP_GEMAC_CPTS0_TS_SYNC | ||||||||||||

| ALT-2 | TIMER_IO1 | ||||||||||||

| ALT-3 | UART2_TXD | ||||||||||||

| ALT-7 | GPIO1_43 | ||||||||||||

| J2.81 | AP | SDIO_A_DATA3 | S | IO | MMC1_DAT3 | SoC | D22 | VDD_3V3 | VDDSHV5 | ALT-0 | MMC1_DAT3 | ||

| ALT-1 | CP_GEMAC_CPTS0_TS_COMP | ||||||||||||

| ALT-2 | TIMER_IO0 | ||||||||||||

| ALT-3 | UART2_RXD | ||||||||||||

| ALT-7 | GPIO1_42 | ||||||||||||

| J2.83 | AP | SDIO_A_CMD | S | IO | MMC1_CMD | SoC | A21 | VDD_3V3 | VDDSHV5 | ALT-0 | MMC1_CMD | ||

| ALT-2 | TIMER_IO5 | ||||||||||||

| ALT-3 | UART3_TXD | ||||||||||||

| ALT-7 | GPIO1_47 | ||||||||||||

| J2.85 | AP | SDIO_A_CLK | S | O | MMC1_CLK | SoC | B22 | VDD_3V3 | VDDSHV5 | ALT-0 | MMC1_CLK | ||

| ALT-2 | TIMER_IO4 | ||||||||||||

| ALT-3 | UART3_RXD | ||||||||||||

| ALT-7 | GPIO1_46 | ||||||||||||

| J2.87 | AP | DGND | G | DGND | |||||||||

| J2.89 | VAR | VAR_B_89 | S | IO | GPMC0_AD11 | SoC | R21 | VDD_3V3 | VDDSHV3 | BOOTMODE11 | ALT-0 | GPMC0_AD11 | |

| ALT-1 | VOUT0_DATA19 | ||||||||||||

| ALT-2 | UART3_TXD | ||||||||||||

| ALT-3 | MCASP2_AXR3 | ||||||||||||

| ALT-4 | PR0_PRU1_GPO3 | ||||||||||||

| ALT-5 | PR0_PRU1_GPI3 | ||||||||||||

| ALT-6 | TRC_DATA23 | ||||||||||||

| ALT-7 | GPIO0_26 | ||||||||||||

| J2.91 | VAR | VAR_B_91 | S | IO | GPMC0_AD10 | SoC | T25 | VDD_3V3 | VDDSHV3 | BOOTMODE10 | ALT-0 | GPMC0_AD10 | |

| ALT-1 | VOUT0_DATA18 | ||||||||||||

| ALT-2 | UART3_RXD | ||||||||||||

| ALT-3 | MCASP2_AXR2 | ||||||||||||

| ALT-4 | PR0_PRU1_GPO2 | ||||||||||||

| ALT-5 | PR0_PRU1_GPI2 | ||||||||||||

| ALT-7 | GPIO0_25 | ||||||||||||

| ALT-8 | OBSCLK0 | ||||||||||||

| J2.93 | AP | UART_C_TX | S | IO | GPMC0_AD09 | SoC | R25 | VDD_3V3 | VDDSHV3 | BOOTMODE09 | ALT-0 | GPMC0_AD9 | |

| ALT-1 | VOUT0_DATA17 | ||||||||||||

| ALT-2 | UART2_TXD | ||||||||||||

| ALT-3 | MCASP2_AXR1 | ||||||||||||

| ALT-4 | PR0_PRU1_GPO1 | ||||||||||||

| ALT-5 | PR0_PRU1_GPI1 | ||||||||||||

| ALT-7 | GPIO0_24 | ||||||||||||

| J2.95 | AP | UART_C_RX | S | IO | GPMC0_AD08 | SoC | R24 | VDD_3V3 | VDDSHV3 | BOOTMODE08 | ALT-0 | GPMC0_AD8 | |

| ALT-1 | VOUT0_DATA16 | ||||||||||||

| ALT-2 | UART2_RXD | ||||||||||||

| ALT-3 | MCASP2_AXR0 | ||||||||||||

| ALT-4 | PR0_PRU1_GPO0 | ||||||||||||

| ALT-5 | PR0_PRU1_GPI0 | ||||||||||||

| ALT-7 | GPIO0_23 | ||||||||||||

| J2.97 | VAR | VAR_B_97 | S | IO | GPMC0_AD13 | SoC | T24 | VDD_3V3 | VDDSHV3 | BOOTMODE13 | ALT-0 | GPMC0_AD13 | |

| ALT-1 | VOUT0_DATA21 | ||||||||||||

| ALT-2 | UART4_TXD | ||||||||||||

| ALT-3 | MCASP2_ACLKX | ||||||||||||

| ALT-4 | PR0_PRU0_GPO1 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI1 | ||||||||||||

| ALT-6 | TRC_DATA21 | ||||||||||||

| ALT-7 | GPIO0_28 | ||||||||||||

| J2.99 | VAR | VAR_B_99 | S | IO | GPMC0_AD12 | SoC | T22 | VDD_3V3 | VDDSHV3 | BOOTMODE12 | ALT-0 | GPMC0_AD12 | |

| ALT-1 | VOUT0_DATA20 | ||||||||||||

| ALT-2 | UART4_RXD | ||||||||||||

| ALT-3 | MCASP2_AFSX | ||||||||||||

| ALT-4 | PR0_PRU0_GPO0 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI0 | ||||||||||||

| ALT-6 | TRC_DATA22 | ||||||||||||

| ALT-7 | GPIO0_27 | ||||||||||||

| J2.101 | AP | I2C_A_SCL | S | IO | GPMC0_CS2# | SoC | K22 | VDD_3V3 | VDDSHV3 | CMOS | ALT-0 | GPMC0_CS2# | |

| ALT-1 | I2C2_SCL | ||||||||||||

| ALT-2 | MCASP1_AXR4 | ||||||||||||

| ALT-3 | UART4_RXD | ||||||||||||

| ALT-4 | PR0_PRU0_GPO19 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI19 | ||||||||||||

| ALT-6 | TRC_DATA17 | ||||||||||||

| ALT-7 | GPIO0_43 | ||||||||||||

| ALT-8 | MCASP1_AFSR | ||||||||||||

| J2.103 | AP | I2C_A_SDA | S | IO | GPMC0_CS3# | SoC | K24 | VDD_3V3 | VDDSHV3 | CMOS | ALT-0 | GPMC0_CS3# | |

| ALT-1 | I2C2_SDA | ||||||||||||

| ALT-2 | GPMC0_A20 | ||||||||||||

| ALT-3 | UART4_TXD | ||||||||||||

| ALT-4 | MCASP1_AXR5 | ||||||||||||

| ALT-6 | TRC_DATA18 | ||||||||||||

| ALT-7 | GPIO0_44 | ||||||||||||

| ALT-8 | MCASP1_ACLKR | ||||||||||||

| J2.105 | VAR | VAR_B_105 | S | IO | GPMC0_AD15 | SoC | U24 | VDD_3V3 | VDDSHV3 | BOOTMODE15 | ALT-0 | GPMC0_AD15 | |

| ALT-1 | VOUT0_DATA23 | ||||||||||||

| ALT-2 | UART5_TXD | ||||||||||||

| ALT-3 | MCASP2_ACLKR | ||||||||||||

| ALT-4 | PR0_PRU0_GPO3 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI3 | ||||||||||||

| ALT-6 | TRC_DATA19 | ||||||||||||

| ALT-7 | GPIO0_30 | ||||||||||||

| ALT-8 | UART2_RTSn | ||||||||||||

| J2.107 | VAR | VAR_B_107 | S | IO | GPMC0_AD14 | SoC | U25 | VDD_3V3 | VDDSHV3 | BOOTMODE14 | ALT-0 | GPMC0_AD14 | |

| ALT-1 | VOUT0_DATA22 | ||||||||||||

| ALT-2 | UART5_RXD | ||||||||||||

| ALT-3 | MCASP2_AFSR | ||||||||||||

| ALT-4 | PR0_PRU0_GPO2 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI2 | ||||||||||||

| ALT-6 | TRC_DATA20 | ||||||||||||

| ALT-7 | GPIO0_29 | ||||||||||||

| ALT-8 | UART2_CTSn | ||||||||||||

| J2.109 | AP | DGND | G | DGND | |||||||||

| J2.111 | VAR | VAR_A_111 | S | IO | MCASP0_AXR1 | SoC | B18 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_AXR1 | ||

| ALT-1 | SPI2_CS2 | ||||||||||||

| ALT-2 | ECAP1_IN_APWM_OUT | ||||||||||||

| ALT-5 | PR0_UART0_RXD | ||||||||||||

| ALT-6 | EHRPWM1_A | ||||||||||||

| ALT-7 | GPIO1_9 | ||||||||||||

| ALT-8 | EQEP0_S | ||||||||||||

| J2.113 | VAR | VAR_A_113 | S | IO | SPI0_CS1 | SoC | C13 | VDD_3V3 | VDDSHV0 | ALT-0 | SPI0_CS1 | ||

| ALT-1 | CP_GEMAC_CPTS0_TS_COMP | ||||||||||||

| ALT-2 | EHRPWM0_B | ||||||||||||

| ALT-3 | ECAP0_IN_APWM_OUT | ||||||||||||

| ALT-7 | GPIO1_16 | ||||||||||||

| ALT-9 | EHRPWM_TZn_IN5 | ||||||||||||

| J2.115 | VAR | VAR_A_115 | OD | IO | MCU_I2C0_SCL | SoC | A8 | VDD_3V3 | VDDSHV_MCU | Internal 4K7 pull-up | ALT-0 | MCU_I2C0_SCL | |

| ALT-7 | MCU_GPIO0_17 | ||||||||||||

| J2.117 | VAR | VAR_A_117 | OD | IO | MCU_I2C0_SDA | SoC | D10 | VDD_3V3 | VDDSHV_MCU | Internal 4K7 pull-up | ALT-0 | MCU_I2C0_SDA | |

| ALT-7 | MCU_GPIO0_18 | ||||||||||||

| J2.119 | AP | GPIO_IRQ_A | S | IO | UART0_RTS# | SoC | B15 | VDD_3V3 | VDDSHV0 | ALT-0 | UART0_RTSn | ||

| ALT-1 | SPI0_CS3 | ||||||||||||

| ALT-2 | I2C3_SDA | ||||||||||||

| ALT-3 | UART2_TXD | ||||||||||||

| ALT-4 | TIMER_IO7 | ||||||||||||

| ALT-5 | AUDIO_EXT_REFCLK1 | ||||||||||||

| ALT-6 | PR0_ECAP0_IN_APWM_OUT | ||||||||||||

| ALT-7 | GPIO1_23 | ||||||||||||

| ALT-8 | MCASP2_ACLKX | ||||||||||||

| ALT-9 | MMC2_SDWP | ||||||||||||

| J2.121 | AP | GPIO_IRQ_B | S | IO | SPI0_D1 | SoC | B14 | VDD_3V3 | VDDSHV0 | ALT-0 | SPI0_D1 | ||

| ALT-1 | CP_GEMAC_CPTS0_HW2TSPUSH | ||||||||||||

| ALT-2 | EHRPWM_TZn_IN0 | ||||||||||||

| ALT-7 | GPIO1_19 | ||||||||||||

| J2.123 | AP | GPIO_A | S | IO | SPI0_D0 | SoC | B13 | VDD_3V3 | VDDSHV0 | ALT-0 | SPI0_D0 | ||

| ALT-1 | CP_GEMAC_CPTS0_HW1TSPUSH | ||||||||||||

| ALT-2 | EHRPWM1_B | ||||||||||||

| ALT-7 | GPIO1_18 | ||||||||||||

| J2.125 | AP | GPIO_B | S | IO | MCASP0_ACLKR | SoC | A20 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_ACLKR | ||

| ALT-1 | SPI2_CLK | ||||||||||||

| ALT-2 | UART1_TXD | ||||||||||||

| ALT-6 | EHRPWM0_B | ||||||||||||

| ALT-7 | GPIO1_14 | ||||||||||||

| ALT-8 | EQEP1_I | ||||||||||||

| J2.127 | VAR | VAR_A_127 | S | IO | VOUT_DATA12 | SoC | AB25 | VDD_3V3 | VDDSHV3 | ALT-0 | VOUT0_DATA12 | ||

| ALT-1 | GPMC0_A12 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO11 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI11 | ||||||||||||

| ALT-4 | UART5_RTSn | ||||||||||||

| ALT-5 | PR0_PRU0_GPO2 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI2 | ||||||||||||

| ALT-7 | GPIO0_57 | ||||||||||||

| J2.129 | VAR | VAR_A_129 | S | IO | GPMC0_WAIT1 | SoC | V25 | VDD_3V3 | VDDSHV3 | ALT-0 | GPMC0_WAIT1 | ||

| ALT-1 | VOUT0_EXTPCLKIN | ||||||||||||

| ALT-2 | GPMC0_A21 | ||||||||||||

| ALT-3 | UART6_RXD | ||||||||||||

| ALT-7 | GPIO0_38 | ||||||||||||

| ALT-8 | EQEP2_I | ||||||||||||

| J2.131 | AP | DGND | G | DGND | |||||||||

| J2.133 | AP | LVDS_A_CLK_N | D | O | OLDI0_CLK0_N | SoC | AD4 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_CLK0_N | |||

| J2.135 | AP | LVDS_A_CLK_P | D | O | OLDI0_CLK0_P | SoC | AE3 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_CLK0_P | |||

| J2.137 | AP | LVDS_A_TX0_N | D | O | OLDI0_A0_N | SoC | AA5 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A0_N | |||

| J2.139 | AP | LVDS_A_TX0_P | D | O | OLDI0_A0_P | SoC | Y6 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A0_P | |||

| J2.141 | AP | LVDS_A_TX1_N | D | O | OLDI0_A1_N | SoC | AD3 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A1_N | |||

| J2.143 | AP | LVDS_A_TX1_P | D | O | OLDI0_A1_P | SoC | AB4 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A1_P | |||

| J2.145 | AP | LVDS_A_TX2_N | D | O | OLDI0_A2_N | SoC | Y8 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A2_N | |||

| J2.147 | AP | LVDS_A_TX2_P | D | O | OLDI0_A2_P | SoC | AA8 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A2_P | |||

| J2.149 | AP | LVDS_A_TX3_N | D | O | OLDI0_A3_N | SoC | AB6 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A3_N | |||

| J2.151 | AP | LVDS_A_TX3_P | D | O | OLDI0_A3_P | SoC | AA7 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A3_P | |||

| J2.153 | AP | DGND | G | DGND | |||||||||

| J2.155 | VAR | VAR_DIF_A_155 | D | O | OLDI0_CLK1_N | SoC | AE4 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_CLK1_N | |||

| J2.157 | VAR | VAR_DIF_A_157 | D | O | OLDI0_CLK1_P | SoC | AD5 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_CLK1_P | |||

| J2.159 | VAR | VAR_DIF_A_159 | D | O | OLDI0_A4_N | SoC | AC6 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A4_N | |||

| J2.161 | VAR | VAR_DIF_A_161 | D | O | OLDI0_A4_P | SoC | AC5 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A4_P | |||

| J2.163 | VAR | VAR_DIF_A_163 | D | O | OLDI0_A5_N | SoC | AE5 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A5_N | |||

| J2.165 | VAR | VAR_DIF_A_165 | D | O | OLDI0_A5_P | SoC | AD6 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A5_P | |||

| J2.167 | VAR | VAR_DIF_A_167 | D | O | OLDI0_A6_N | SoC | AE6 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A6_N | |||

| J2.169 | VAR | VAR_DIF_A_169 | D | O | OLDI0_A6_P | SoC | AD7 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A6_P | |||

| J2.171 | VAR | VAR_DIF_A_171 | D | O | OLDI0_A7_N | SoC | AD8 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A7_N | |||

| J2.173 | VAR | VAR_DIF_A_173 | D | O | OLDI0_A7_P | SoC | AE7 | VDD_1V8 | VDDA_1P8_OLDI | OLDI0_A7_P | |||

| J2.175 | AP | DGND | G | DGND | |||||||||

| J2.177 | AP | SDIO_A_CardDetect | S | I | MMC1_SDCD | SoC | D17 | VDD_3V3 | VDDSHV0 | ALT-0 | MMC1_SDCD | ||

| ALT-1 | UART6_RXD | ||||||||||||

| ALT-2 | TIMER_IO6 | ||||||||||||

| ALT-3 | UART3_RTSn | ||||||||||||

| ALT-7 | GPIO1_48 | ||||||||||||

| J2.179 | AP | SPI_A_SS0 | S | IO | OSPI0_D4 | SoC | J23 | VDD_3V3 | VDDSHV1 | ALT-0 | OSPI0_D4 | ||

| ALT-1 | SPI1_CS0 | ||||||||||||

| ALT-2 | MCASP1_AXR1 | ||||||||||||

| ALT-3 | UART6_RXD | ||||||||||||

| ALT-7 | GPIO0_7 | ||||||||||||

| J2.181 | AP | SPI_A_SCLK | S | IO | OSPI0_D5 | SoC | J25 | VDD_3V3 | VDDSHV1 | ALT-0 | OSPI0_D5 | ||

| ALT-1 | SPI1_CLK | ||||||||||||

| ALT-2 | MCASP1_AXR0 | ||||||||||||

| ALT-3 | UART6_TXD | ||||||||||||

| ALT-7 | GPIO0_8 | ||||||||||||

| J2.183 | AP | SPI_A_MISO | S | IO | OSPI0_D7 | SoC | J22 | VDD_3V3 | VDDSHV1 | ALT-0 | OSPI0_D7 | ||

| ALT-1 | SPI1_D1 | ||||||||||||

| ALT-2 | MCASP1_AFSX | ||||||||||||

| ALT-3 | UART6_CTSn | ||||||||||||

| ALT-7 | GPIO0_10 | ||||||||||||

| J2.185 | AP | SPI_A_MOSI | S | IO | OSPI0_D6 | SoC | H25 | VDD_3V3 | VDDSHV1 | ALT-0 | OSPI0_D6 | ||

| ALT-1 | SPI1_D0 | ||||||||||||

| ALT-2 | MCASP1_ACLKX | ||||||||||||

| ALT-3 | UART6_RTSn | ||||||||||||

| ALT-3 | GPIO0_9 | ||||||||||||

| J2.187 | AP | UART_A_TX | S | IO | UART0_TXD | SoC | E14 | VDD_3V3 | VDDSHV0 | ALT-0 | UART0_TXD | ||

| ALT-1 | ECAP2_IN_APWM_OUT | ||||||||||||

| ALT-2 | SPI2_D1 | ||||||||||||

| ALT-3 | EHRPWM2_B | ||||||||||||

| ALT-7 | GPIO1_21 | ||||||||||||

| J2.189 | AP | UART_A_RX | S | IO | UART0_RXD | SoC | D14 | VDD_3V3 | VDDSHV0 | ALT-0 | UART0_RXD | ||

| ALT-1 | ECAP1_IN_APWM_OUT | ||||||||||||

| ALT-2 | SPI2_D0 | ||||||||||||

| ALT-3 | EHRPWM2_A | ||||||||||||

| ALT-7 | GPIO1_20 | ||||||||||||

| J2.191 | VAR | VAR_B_191 | S | IO | OSPI0_CS2# | SoC | H21 | VDD_3V3 | VDDSHV1 | ALT-0 | OSPI0_CSn2 | ||

| ALT-1 | SPI1_CS1 | ||||||||||||

| ALT-2 | OSPI0_RESET_OUT1 | ||||||||||||

| ALT-3 | MCASP1_AFSR | ||||||||||||

| ALT-4 | MCASP1_AXR2 | ||||||||||||

| ALT-5 | UART5_RXD | ||||||||||||

| ALT-7 | GPIO0_13 | ||||||||||||

| J2.193 | VAR | VAR_A_193 | S | IO | WKUP_UART0_TXD | SoC | C5 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | WKUP_UART0_TXD | ||

| ALT-2 | MCU_SPI1_CS2 | ||||||||||||

| ALT-7 | MCU_GPIO0_10 | ||||||||||||

| J2.195 | VAR | VAR_A_195 | S | IO | WKUP_UART0_RXD | SoC | B4 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | WKUP_UART0_RXD | ||

| ALT-2 | MCU_SPI0_CS2 | ||||||||||||

| ALT-7 | MCU_GPIO0_9 | ||||||||||||

| J2.197 | VAR | VAR_A_197 | S | IO | GPMC0_AD00 | SoC | M25 | VDD_3V3 | VDDSHV3 | BOOTMODE00 | ALT-0 | GPMC0_AD0 | |

| ALT-1 | PR0_PRU1_GPO8 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI8 | ||||||||||||

| ALT-3 | MCASP2_AXR4 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO0 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI0 | ||||||||||||

| ALT-6 | TRC_CLK | ||||||||||||

| ALT-7 | GPIO0_15 | ||||||||||||

| J2.199 | VAR | VAR_A_199 | S | IO | MCASP0_AFSR | SoC | E19 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_AFSR | ||

| ALT-1 | SPI2_CS0 | ||||||||||||

| ALT-2 | UART1_RXD | ||||||||||||

| ALT-6 | EHRPWM0_A | ||||||||||||

| ALT-7 | GPIO1_13 | ||||||||||||

| ALT-8 | EQEP1_S | ||||||||||||

| J2.201 | VAR | VAR_A_201 | S | IO | GPMC0_WE# | SoC | L25 | VDD_3V3 | VDDSHV3 | ALT-0 | GPMC0_WEn | ||

| ALT-2 | MCASP1_AXR0 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO11 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI11 | ||||||||||||

| ALT-6 | TRC_DATA9 | ||||||||||||

| ALT-7 | GPIO0_34 | ||||||||||||

| J2.203 | AP | DGND | G | DGND | |||||||||

Pinout Table ODD pins declaration[edit | edit source]

| Pin | Pin Type | UNICA pin name | Type | DADA pin name | Internal Connections | Ball/pin # | SoM Voltage domain | SoC Voltage domain | Notes | Boot Mode | Alternative mux modes | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| J2.2 | AP | DGND | G | DGND | |||||||||

| J2.4 | AP | VIN_SOM | PWR | +VIN_SOM | VIN_SOM | ||||||||

| J2.6 | AP | VIN_SOM | PWR | +VIN_SOM | VIN_SOM | ||||||||

| J2.8 | AP | VIN_SOM | PWR | +VIN_SOM | VIN_SOM | ||||||||

| J2.10 | AP | VIN_SOM | PWR | +VIN_SOM | VIN_SOM | ||||||||

| J2.12 | AP | DGND | G | DGND | |||||||||

| J2.14 | VAR | WARM_RESET | OD | I | WARM_RESET | RST | - | VDD_3V3 | Internal 10K pull-upll-up | ||||

| J2.16 | VAR | ONOFF_STDBY | OD | I | ONOFF_STDBY | PMIC | 25 | VIN_SOM | Internal 10K pull-upll-up | ||||

| J2.18 | AP | SOM_PGOOD | PP | O | SOM_PGOOD | VM | - | VIN_SOM | |||||

| J2.20 | AP | BOOT_MODE_SEL | OD | I | BOOT_MODE_SEL | BOOT | - | VDD_3V3 | Internal 10K pull-up | ||||

| J2.22 | VAR | POR_OUT | OD | O | POR_OUT | RST | - | VIN_SOM | Pull-up on the carrier | ||||

| J2.24 | AP | COLD_RESET | OD | I | COLD_RESET | RST | - | VDD_3V3 | Internal 10K pull-up | ||||

| J2.26 | VAR | VAR_B_26 | S | IO | GPMC0_AD01 | SoC | N23 | VDD_3V3 | VDDSHV3 | BOOTMODE01 | ALT-0 | GPMC0_AD1 | |

| ALT-1 | PR0_PRU1_GPO9 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI9 | ||||||||||||

| ALT-3 | MCASP2_AXR5 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO1 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI1 | ||||||||||||

| ALT-6 | TRC_CTL | ||||||||||||

| ALT-7 | GPIO0_16 | ||||||||||||

| J2.28 | AP | PWM_A | S | O | SPI0_CS0 | SoC | A13 | VDD_3V3 | VDDSHV0 | ALT-0 | SPI0_CS0 | ||

| ALT-2 | EHRPWM0_A | ||||||||||||

| ALT-6 | PR0_ECAP0_SYNC_IN | ||||||||||||

| ALT-7 | GPIO1_15 | ||||||||||||

| J2.30 | AP | DGND | G | DGND | |||||||||

| J2.32 | VAR | VAR_B_32 | S | IO | GPMC0_AD07 | SoC | R23 | VDD_3V3 | VDDSHV3 | BOOTMODE07 | ALT-0 | GPMC0_AD7 | |

| ALT-1 | PR0_PRU1_GPO15 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI15 | ||||||||||||

| ALT-3 | MCASP2_AXR11 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO7 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI7 | ||||||||||||

| ALT-6 | TRC_DATA5 | ||||||||||||

| ALT-7 | GPIO0_22 | ||||||||||||

| J2.34 | VAR | VAR_B_34 | S | IO | GPMC0_AD04 | SoC | P24 | VDD_3V3 | VDDSHV3 | BOOTMODE04 | ALT-0 | GPMC0_AD4 | |

| ALT-1 | PR0_PRU1_GPO12 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI12 | ||||||||||||

| ALT-3 | MCASP2_AXR8 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO4 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI4 | ||||||||||||

| ALT-6 | TRC_DATA2 | ||||||||||||

| ALT-7 | GPIO0_19 | ||||||||||||

| J2.36 | VAR | VAR_B_36 | S | IO | SPI0_CLK | SoC | A14 | VDD_3V3 | VDDSHV0 | ALT-0 | SPI0_CLK | ||

| ALT-1 | CP_GEMAC_CPTS0_TS_SYNC | ||||||||||||

| ALT-2 | EHRPWM1_A | ||||||||||||

| ALT-3 | GPIO1_17 | ||||||||||||

| J2.38 | AP | I2C_B_SCL | S | O | I2C1_SCL | SoC | B17 | VDD_3V3 | VDDSHV0 | Internal Internal 4K7 pull-upll-up, CMOS | ALT-0 | I2C1_SCL | |

| ALT-1 | UART1_RXD | ||||||||||||

| ALT-2 | TIMER_IO0 | ||||||||||||

| ALT-3 | SPI2_CS1 | ||||||||||||

| ALT-4 | EHRPWM0_SYNCI | ||||||||||||

| ALT-7 | GPIO1_28 | ||||||||||||

| ALT-8 | EHRPWM2_A | ||||||||||||

| ALT-9 | MMC2_SDCD | ||||||||||||

| J2.40 | AP | I2C_B_SDA | S | IO | I2C1_SDA | SoC | A17 | VDD_3V3 | VDDSHV0 | Internal Internal 4K7 pull-upll-up, CMOS | ALT-0 | I2C1_SDA | |

| ALT-1 | UART1_TXD | ||||||||||||

| ALT-2 | TIMER_IO1 | ||||||||||||

| ALT-3 | SPI2_CLK | ||||||||||||

| ALT-4 | EHRPWM0_SYNCO | ||||||||||||

| ALT-7 | GPIO1_29 | ||||||||||||

| ALT-8 | EHRPWM2_B | ||||||||||||

| ALT-9 | MMC2_SDWP | ||||||||||||

| J2.42 | AP | CAN_A_TX | S | O | MCAN0_TX | SoC | C15 | VDD_3V3 | VDDSHV0 | ALT-0 | MCAN0_TX | ||

| ALT-1 | UART5_RXD | ||||||||||||

| ALT-2 | TIMER_IO2 | ||||||||||||

| ALT-3 | SYNC2_OUT | ||||||||||||

| ALT-4 | UART1_DTRn | ||||||||||||

| ALT-5 | EQEP2_I | ||||||||||||

| ALT-6 | PR0_UART0_RXD | ||||||||||||

| ALT-7 | GPIO1_24 | ||||||||||||

| ALT-8 | MCASP2_AXR0 | ||||||||||||

| ALT-9 | EHRPWM_TZn_IN3 | ||||||||||||

| J2.44 | AP | CAN_A_RX | S | I | MCAN0_RX | SoC | E15 | VDD_3V3 | VDDSHV0 | ALT-0 | MCAN0_RX | ||

| ALT-1 | UART5_TXD | ||||||||||||

| ALT-2 | TIMER_IO3 | ||||||||||||

| ALT-3 | SYNC3_OUT | ||||||||||||

| ALT-4 | UART1_RIn | ||||||||||||

| ALT-5 | EQEP2_S | ||||||||||||

| ALT-6 | PR0_UART0_TXD | ||||||||||||

| ALT-7 | GPIO1_25 | ||||||||||||

| ALT-8 | MCASP2_AXR1 | ||||||||||||

| ALT-9 | EHRPWM_TZn_IN4 | ||||||||||||

| J2.46 | VAR | VAR_B_46 | S | I | JTAG_TRST | SoC | B10 | VDD_3V3 | VDDSHV_MCU | Internal 10K pull-down | TRSTN | ||

| J2.48 | AP | JTAG_TDI | S | I | JTAG_TDI | SoC | A11 | VDD_3V3 | VDDSHV_MCU | TDI | |||

| J2.50 | AP | JTAG_TMS | S | I | JTAG_TMS | SoC | B11 | VDD_3V3 | VDDSHV_MCU | TMS | |||

| J2.52 | AP | JTAG_TCK | S | I | JTAG_TCK | SoC | A10 | VDD_3V3 | VDDSHV_MCU | TCK | |||

| J2.54 | AP | JTAG_TDO | S | O | JTAG_TDO | SoC | D12 | VDD_3V3 | VDDSHV_MCU | TDO | |||

| J2.56 | AP | DGND | G | DGND | |||||||||

| J2.58 | VAR | VAR_B_58 | S | IO | MCU_MCAN0_TX | SoC | D6 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_MCAN0_TX | ||

| ALT-1 | WKUP_TIMER_IO0 | ||||||||||||

| ALT-2 | MCU_SPI0_CS3 | ||||||||||||

| ALT-7 | MCU_GPIO0_13 | ||||||||||||

| J2.60 | VAR | VAR_B_60 | S | IO | MCU_MCAN0_RX | SoC | B3 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_MCAN0_RX | ||

| ALT-1 | MCU_TIMER_IO0 | ||||||||||||

| ALT-2 | MCU_SPI1_CS3 | ||||||||||||

| ALT-7 | MCU_GPIO0_14 | ||||||||||||

| J2.62 | AP | CONFIG_ID (1wire) | S | IO | CB_CONFIG_ID | 1wM | - | ||||||

| J2.64 | AP | Audio_MCLK | S | O | UART0_CTS# | SoC | A15 | VDD_3V3 | VDDSHV0 | ALT-0 | UART0_CTSn | ||

| ALT-1 | SPI0_CS2 | ||||||||||||

| ALT-2 | I2C3_SCL | ||||||||||||

| ALT-3 | UART2_RXD | ||||||||||||

| ALT-4 | TIMER_IO6 | ||||||||||||

| ALT-5 | AUDIO_EXT_REFCLK0 | ||||||||||||

| ALT-6 | PR0_ECAP0_SYNC_OUT | ||||||||||||

| ALT-7 | GPIO1_22 | ||||||||||||

| ALT-8 | MCASP2_AFSX | ||||||||||||

| ALT-9 | MMC2_SDCD | ||||||||||||

| J2.66 | AP | Audio_BCLK | S | O | MCASP0_ACLKX | SoC | B20 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_ACLKX | ||

| ALT-1 | SPI2_CS1 | ||||||||||||

| ALT-2 | ECAP2_IN_APWM_OUT | ||||||||||||

| ALT-7 | GPIO1_11 | ||||||||||||

| ALT-8 | EQEP1_A | ||||||||||||

| J2.68 | AP | Audio_DOUT | S | O | MCASP0_AXR0 | SoC | E18 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_AXR0 | ||

| ALT-1 | PR0_ECAP0_IN_APWM_OUT | ||||||||||||

| ALT-2 | AUDIO_EXT_REFCLK0 | ||||||||||||

| ALT-5 | PR0_UART0_TXD | ||||||||||||

| ALT-6 | EHRPWM1_B | ||||||||||||

| ALT-7 | GPIO1_10 | ||||||||||||

| ALT-8 | EQEP0_I | ||||||||||||

| J2.70 | AP | Audio_WCLK | S | O | MCASP0_AFSX | SoC | D20 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_AFSX | ||

| ALT-1 | SPI2_CS3 | ||||||||||||

| ALT-2 | AUDIO_EXT_REFCLK1 | ||||||||||||

| ALT-7 | GPIO1_12 | ||||||||||||

| ALT-8 | EQEP1_B | ||||||||||||

| J2.72 | AP | Audio_DIN | S | I | MCASP0_AXR2 | SoC | A19 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_AXR2 | ||

| ALT-1 | SPI2_D1 | ||||||||||||

| ALT-2 | UART1_RTSn | ||||||||||||

| ALT-3 | UART6_TXD | ||||||||||||

| ALT-4 | PR0_IEP0_EDIO_DATA_IN_OUT29 | ||||||||||||

| ALT-5 | ECAP2_IN_APWM_OUT | ||||||||||||

| ALT-6 | PR0_UART0_TXD | ||||||||||||

| ALT-7 | GPIO1_8 | ||||||||||||

| ALT-8 | EQEP0_B | ||||||||||||

| J2.74 | VAR | VAR_B_74 | S | O | I2C0_SCL | SoC | B16 | VDD_3V3 | VDDSHV0 | Internal Internal 4K7 pull-upll-up, CMOS | ALT-0 | I2C0_SCL | |

| ALT-1 | PR0_IEP0_EDIO_DATA_IN_OUT30 | ||||||||||||

| ALT-2 | SYNC0_OUT | ||||||||||||

| ALT-3 | OBSCLK0 | ||||||||||||

| ALT-4 | UART1_DCDn | ||||||||||||

| ALT-5 | EQEP2_A | ||||||||||||

| ALT-6 | EHRPWM_SOCA | ||||||||||||

| ALT-7 | GPIO1_26 | ||||||||||||

| ALT-8 | ECAP1_IN_APWM_OUT | ||||||||||||

| ALT-9 | SPI2_CS0 | ||||||||||||

| J2.76 | VAR | VAR_B_76 | S | IO | I2C0_SDA | SoC | A16 | VDD_3V3 | VDDSHV0 | Internal Internal 4K7 pull-upll-up, CMOS | ALT-0 | I2C0_SDA | |

| ALT-1 | PR0_IEP0_EDIO_DATA_IN_OUT31 | ||||||||||||

| ALT-2 | SPI2_CS2 | ||||||||||||

| ALT-3 | TIMER_IO5 | ||||||||||||

| ALT-4 | UART1_DSRn | ||||||||||||

| ALT-5 | EQEP2_B | ||||||||||||

| ALT-6 | EHRPWM_SOCB | ||||||||||||

| ALT-7 | GPIO1_27 | ||||||||||||

| ALT-8 | ECAP2_IN_APWM_OUT | ||||||||||||

| J2.78 | VAR | VAR_B_78 | OD | IO | ETH_INT | LAN | 39 | VDD_3V3 | Internal 4K7 pull-up | ||||

| J2.78 | VAR | VAR_B_78 (*) | OD | IO | ETH_INT | SoC | AB24 | VDD_3V3 | VDDSHV3 | Hardware mounting option (*) | ALT-0 | VOUT0_HSYNC | |

| ALT-1 | GPMC0_A16 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO15 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI15 | ||||||||||||

| ALT-4 | UART3_RTSn | ||||||||||||

| ALT-5 | PR0_PRU0_GPO6 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI6 | ||||||||||||

| ALT-7 | GPIO0_61 | ||||||||||||

| J2.80 | VAR | VAR_B_80 | OD | O | ETH_RST# | LAN | 43 | VDD_RGMII | Internal 10K pull-up | ||||

| J2.80 | VAR | VAR_B_80 (*) | OD | O | ETH_RST# | SoC | AA24 | VDD_3V3 | VDDSHV3 | Hardware mounting option (*) | ALT-0 | VOUT0_DATA13 | |

| ALT-1 | GPMC0_A13 | ||||||||||||

| ALT-2 | PR0_PRU1_GPO12 | ||||||||||||

| ALT-3 | PR0_PRU1_GPI12 | ||||||||||||

| ALT-4 | UART5_CTSn | ||||||||||||

| ALT-5 | PR0_PRU0_GPO3 | ||||||||||||

| ALT-6 | PR0_PRU0_GPI3 | ||||||||||||

| ALT-7 | GPIO0_58 | ||||||||||||

| J2.82 | AP | DGND | G | DGND | |||||||||

| J2.84 | VAR | VAR_DIF_B_84 | D | WKUP_CLKOUT0 | SoC | A12 | VDD_3V3 | VDDSHV_MCU | Hardware mounting option (*) | WKUP_CLKOUT0 | |||

| J2.86 | VAR | VAR_DIF_B_86 | D | EXT_REFCLK1 | SoC | A18 | VDD_3V3 | VDDSHV0 | Hardware mounting option (*) | ALT-0 | SYNC1_OUT | ||

| ALT-2 | SPI2_CS3 | ||||||||||||

| ALT-3 | SYSCLKOUT0 | ||||||||||||

| ALT-4 | TIMER_IO4 | ||||||||||||

| ALT-5 | CLKOUT0 | ||||||||||||

| ALT-6 | CP_GEMAC_CPTS0_RFT_CLK | ||||||||||||

| ALT-7 | GPIO1_30 | ||||||||||||

| ALT-8 | ECAP0_IN_APWM_OUT | ||||||||||||

| J2.88 | VAR | VAR_B_88 | OD | I | EXTINT# | SoC | D16 | VDD_3V3 | VDDSHV0 | ALT-0 | EXTINTn | ||

| ALT-7 | GPIO1_31 | ||||||||||||

| J2.90 | VAR | VAR_DIF_B_90 | D | IO | GPMC0_AD02 | SoC | N24 | VDD_3V3 | VDDSHV3 | BOOTMODE02 | ALT-0 | GPMC0_AD2 | |

| ALT-1 | PR0_PRU1_GPO10 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI10 | ||||||||||||

| ALT-3 | MCASP2_AXR6 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO2 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI2 | ||||||||||||

| ALT-6 | TRC_DATA0 | ||||||||||||

| ALT-7 | GPIO0_17 | ||||||||||||

| J2.92 | VAR | VAR_DIF_B_92 | D | IO | MCU_RESETZ | SoC | E11 | VDD_3V3 | VDDSHV_MCU | MCU_RESETz | |||

| J2.94 | VAR | VAR_DIF_B_94 | D | IO | MCU_RESETSTATZ | SoC | B12 | VDD_3V3 | VDDSHV_MCU | ALT-0 | MCU_RESETSTATz | ||

| ALT-7 | MCU_GPIO0_21 | ||||||||||||

| J2.96 | VAR | VAR_DIF_B_96 | D | IO | MCU_ERROR# | SoC | D1 | VDD_1V8 | VDDS_OSC0 | 1.8 V | MCU_ERRORn | ||

| J2.98 | VAR | VAR_DIF_B_98 | D | IO | MCASP0_AXR3 | SoC | B19 | VDD_3V3 | VDDSHV0 | ALT-0 | MCASP0_AXR3 | ||

| ALT-1 | SPI2_D0 | ||||||||||||

| ALT-2 | UART1_CTSn | ||||||||||||

| ALT-3 | UART6_RXD | ||||||||||||

| ALT-4 | PR0_IEP0_EDIO_DATA_IN_OUT28 | ||||||||||||

| ALT-5 | ECAP1_IN_APWM_OUT | ||||||||||||

| ALT-6 | PR0_UART0_RXD | ||||||||||||

| ALT-7 | GPIO1_7 | ||||||||||||

| ALT-8 | EQEP0_A | ||||||||||||

| J2.100 | AP | DGND | G | DGND | |||||||||

| J2.102 | AP | CSI_CLK_N | D | I | CSI0_RXCLK_N | SoC | AD15 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RXCLK_N | |||

| J2.104 | AP | CSI_CLK_P | D | I | CSI0_RXCLK_P | SoC | AE15 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RXCLK_P | |||

| J2.106 | AP | CSI_D0_N | D | I | CSI0_RX0_N | SoC | AB14 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX0_N | |||

| J2.108 | AP | CSI_D0_P | D | I | CSI0_RX0_P | SoC | AC15 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX0_P | |||

| J2.110 | AP | CSI_D1_N | D | I | CSI0_RX1_N | SoC | AD14 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX1_N | |||

| J2.112 | AP | CSI_D1_P | D | I | CSI0_RX1_P | SoC | AE14 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX1_P | |||

| J2.114 | VAR | VAR_DIF_C_114 | D | I | CSI0_RX2_N | SoC | AD13 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX2_N | |||

| J2.116 | VAR | VAR_DIF_C_116 | D | I | CSI0_RX2_P | SoC | AE13 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX2_P | |||

| J2.118 | VAR | VAR_DIF_C_118 | D | I | CSI0_RX3_N | SoC | AB12 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX3_N | |||

| J2.120 | VAR | VAR_DIF_C_120 | D | I | CSI0_RX3_P | SoC | AC13 | VDD_1V8 | VDDA_1P8_CSIRX | CSI0_RX3_P | |||

| J2.122 | AP | DGND | G | DGND | |||||||||

| J2.124 | VAR | VAR_C_124 | S | IO | GPMC0_AD05 | SoC | P22 | VDD_3V3 | VDDSHV3 | BOOTMODE05 | ALT-0 | GPMC0_AD5 | |

| ALT-1 | PR0_PRU1_GPO13 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI13 | ||||||||||||

| ALT-3 | MCASP2_AXR9 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO5 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI5 | ||||||||||||

| ALT-6 | TRC_DATA3 | ||||||||||||

| ALT-7 | GPIO0_20 | ||||||||||||

| J2.126 | VAR | VAR_C_126 | S | IO | GPMC0_AD06 | SoC | P21 | VDD_3V3 | VDDSHV3 | BOOTMODE06 | ALT-0 | GPMC0_AD6 | |

| ALT-1 | PR0_PRU1_GPO14 | ||||||||||||

| ALT-2 | PR0_PRU1_GPI14 | ||||||||||||

| ALT-3 | MCASP2_AXR10 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO6 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI6 | ||||||||||||

| ALT-6 | TRC_DATA4 | ||||||||||||

| ALT-7 | GPIO0_21 | ||||||||||||

| J2.128 | VAR | VAR_C_128 | OD | IO | WKUP_I2C0_SCL | SoC | B9 | VDD_3V3 | VDDSHV_MCU | Internal 4K7 pull-up | ALT-0 | WKUP_I2C0_SCL | |

| ALT-7 | MCU_GPIO0_19 | ||||||||||||

| J2.130 | VAR | VAR_C_130 | OD | IO | WKUP_I2C0_SDA | SoC | A9 | VDD_3V3 | VDDSHV_MCU | Internal 4K7 pull-up | ALT-0 | WKUP_I2C0_SDA | |

| ALT-7 | MCU_GPIO0_20 | ||||||||||||

| J2.132 | VAR | VAR_C_132 | S | IO | MCU_MCAN1_TX | SoC | E5 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_MCAN1_TX | ||

| ALT-1 | MCU_TIMER_IO2 | ||||||||||||

| ALT-3 | MCU_SPI1_CS1 | ||||||||||||

| ALT-4 | MCU_EXT_REFCLK0 | ||||||||||||

| ALT-7 | MCU_GPIO0_15 | ||||||||||||

| J2.134 | VAR | VAR_C_134 | S | IO | MCU_MCAN1_RX | SoC | D4 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_MCAN1_RX | ||

| ALT-1 | MCU_TIMER_IO3 | ||||||||||||

| ALT-2 | MCU_SPI0_CS2 | ||||||||||||

| ALT-3 | MCU_SPI1_CS2 | ||||||||||||

| ALT-4 | MCU_SPI1_CLK | ||||||||||||

| ALT-7 | MCU_GPIO0_16 | ||||||||||||

| J2.136 | VAR | S | IO | MCU_SPI0_CLK | SoC | A7 | VDD_3V3 | VDDSHV_MCU | ALT-0 | MCU_SPI0_CLK | |||

| ALT-7 | MCU_GPIO0_2 | ||||||||||||

| J2.138 | VAR | VAR_C_138 | S | IO | MCU_SPI0_CS0 | SoC | E8 | VDD_3V3 | VDDSHV_MCU | ALT-0 | MCU_SPI0_CS0 | ||

| ALT-4 | WKUP_TIMER_IO1 | ||||||||||||

| ALT-7 | MCU_GPIO0_0 | ||||||||||||

| J2.140 | VAR | VAR_C_140 | S | IO | MCU_SPI0_CS1 | SoC | B8 | VDD_3V3 | VDDSHV_MCU | ALT-0 | MCU_SPI0_CS1 | ||

| ALT-1 | MCU_OBSCLK0 | ||||||||||||

| ALT-2 | MCU_SYSCLKOUT0 | ||||||||||||

| ALT-3 | MCU_EXT_REFCLK0 | ||||||||||||

| ALT-4 | MCU_TIMER_IO1 | ||||||||||||

| ALT-6 | MCU_GPIO0_1 | ||||||||||||

| J2.142 | VAR | VAR_C_142 | S | IO | MCU_SPI0_D0 | SoC | D9 | VDD_3V3 | VDDSHV_MCU | ALT-0 | MCU_SPI0_D0 | ||

| ALT-7 | MCU_GPIO0_3 | ||||||||||||

| J2.144 | VAR | VAR_C_144 | S | IO | MCU_SPI0_D1 | SoC | C9 | VDD_3V3 | VDDSHV_MCU | ALT-0 | MCU_SPI0_D1 | ||

| ALT-7 | MCU_GPIO0_4 | ||||||||||||

| J2.146 | AP | DGND | G | DGND | |||||||||

| J2.148 | VAR | VAR_C_148 | S | IO | WKUP_UART0_RTS# | SoC | A4 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | WKUP_UART0_RTSn | ||

| ALT-1 | WKUP_TIMER_IO1 | ||||||||||||

| ALT-3 | MCU_SPI1_CLK | ||||||||||||

| ALT-7 | MCU_GPIO0_12 | ||||||||||||

| J2.150 | VAR | VAR_C_150 | S | IO | WKUP_UART0_CTS# | SoC | C6 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | WKUP_UART0_CTSn | ||

| ALT-1 | WKUP_TIMER_IO0 | ||||||||||||

| ALT-3 | MCU_SPI1_CS0 | ||||||||||||

| ALT-7 | MCU_GPIO0_11 | ||||||||||||

| J2.152 | VAR | VAR_C_152 | S | IO | MCU_UART0_CTS# | SoC | A6 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_UART0_CTSn | ||

| ALT-1 | MCU_TIMER_IO0 | ||||||||||||

| ALT-3 | MCU_SPI1_D0 | ||||||||||||

| ALT-7 | MCU_GPIO0_7 | ||||||||||||

| J2.154 | VAR | VAR_C_154 | S | IO | MCU_UART0_RTS# | SoC | B6 | VDD_3V3 | VDDSHV_CANUART | ALT-0 | MCU_UART0_RTSn | ||

| ALT-1 | MCU_TIMER_IO1 | ||||||||||||

| ALT-3 | MCU_SPI1_D1 | ||||||||||||

| ALT-7 | MCU_GPIO0_8 | ||||||||||||

| J2.156 | VAR | VAR_D_156 | S | IO | RGMII2_TD3 | SoC | AC20 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_TD3 | ||

| ALT-2 | MCASP2_ACLKX | ||||||||||||

| ALT-3 | PR0_PRU1_GPO16 | ||||||||||||

| ALT-4 | PR0_PRU1_GPI16 | ||||||||||||

| ALT-5 | PR0_ECAP0_SYNC_OUT | ||||||||||||

| ALT-6 | PR0_UART0_CTSn | ||||||||||||

| ALT-7 | GPIO1_0 | ||||||||||||

| ALT-8 | EQEP2_S | ||||||||||||

| J2.158 | VAR | VAR_D_158 | S | IO | RGMII2_TD2 | SoC | AD21 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_TD2 | ||

| ALT-2 | MCASP2_AFSX | ||||||||||||

| ALT-3 | PR0_PRU1_GPO4 | ||||||||||||

| ALT-4 | PR0_PRU1_GPI4 | ||||||||||||

| ALT-5 | PR0_ECAP0_IN_APWM_OUT | ||||||||||||

| ALT-7 | GPIO0_91 | ||||||||||||

| ALT-8 | EQEP2_I | ||||||||||||

| J2.160 | VAR | VAR_D_160 | S | IO | RGMII2_TD1 | SoC | AA18 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_TD1 | ||

| ALT-1 | RMII2_TXD1 | ||||||||||||

| ALT-2 | MCASP2_ACLKR | ||||||||||||

| ALT-3 | PR0_PRU1_GPO3 | ||||||||||||

| ALT-4 | PR0_PRU1_GPI3 | ||||||||||||

| ALT-5 | MCASP2_AXR8 | ||||||||||||

| ALT-7 | GPIO0_90 | ||||||||||||

| J2.162 | VAR | VAR_D_162 | S | IO | RGMII2_TD0 | SoC | Y18 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_TD0 | ||

| ALT-1 | RMII2_TXD0 | ||||||||||||

| ALT-2 | MCASP2_AXR6 | ||||||||||||

| ALT-3 | PR0_PRU1_GPO2 | ||||||||||||

| ALT-4 | PR0_PRU1_GPI2 | ||||||||||||

| ALT-7 | GPIO0_89 | ||||||||||||

| J2.164 | AP | DGND | G | DGND | |||||||||

| J2.166 | VAR | VAR_D_166 | S | IO | RGMII2_TXC | SoC | AE21 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_TXC | ||

| ALT-1 | RMII2_CRS_DV | ||||||||||||

| ALT-2 | MCASP2_AXR5 | ||||||||||||

| ALT-3 | PR0_PRU1_GPO1 | ||||||||||||

| ALT-4 | PR0_PRU1_GPI1 | ||||||||||||

| ALT-7 | GPIO0_88 | ||||||||||||

| J2.168 | VAR | VAR_D_168 | S | IO | RGMII2_TX_CTL | SoC | AA19 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_TX_CTL | ||

| ALT-1 | RMII2_TX_EN | ||||||||||||

| ALT-2 | MCASP2_AXR4 | ||||||||||||

| ALT-3 | PR0_PRU1_GPO0 | ||||||||||||

| ALT-4 | PR0_PRU1_GPI0 | ||||||||||||

| ALT-7 | GPIO0_87 | ||||||||||||

| J2.170 | VAR | VAR_D_170 | S | IO | MDIO0_MDC | SoC | AD24 | VDD_RGMII | VDDSHV2 | ALT-0 | MDIO0_MDC | ||

| ALT-7 | GPIO0_86 | ||||||||||||

| J2.172 | VAR | VAR_D_172 | S | IO | MDIO0_MDIO | SoC | AB22 | VDD_RGMII | VDDSHV2 | ALT-0 | MDIO0_MDIO | ||

| ALT-7 | GPIO0_85 | ||||||||||||

| J2.174 | VAR | VAR_D_174 | S | IO | RGMII2_RX_CTL | SoC | AD22 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_RX_CTL | ||

| ALT-1 | RMII2_RX_ER | ||||||||||||

| ALT-2 | MCASP2_AXR3 | ||||||||||||

| ALT-3 | PR0_PRU0_GPO0 | ||||||||||||

| ALT-4 | PR0_PRU0_GPI0 | ||||||||||||

| ALT-7 | GPIO1_1 | ||||||||||||

| J2.176 | VAR | VAR_D_176 | S | IO | RGMII2_RD0 | SoC | AE23 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_RD0 | ||

| ALT-1 | RMII2_RXD0 | ||||||||||||

| ALT-2 | MCASP2_AXR2 | ||||||||||||

| ALT-3 | PR0_PRU0_GPO2 | ||||||||||||

| ALT-4 | PR0_PRU0_GPI2 | ||||||||||||

| ALT-5 | PR0_UART0_RTSn | ||||||||||||

| ALT-7 | GPIO1_3 | ||||||||||||

| J2.178 | VAR | VAR_D_178 | S | IO | RGMII2_RD1 | SoC | AB20 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_RD1 | ||

| ALT-1 | RMII2_RXD1 | ||||||||||||

| ALT-2 | MCASP2_AFSR | ||||||||||||

| ALT-3 | PR0_PRU0_GPO3 | ||||||||||||

| ALT-4 | PR0_PRU0_GPI3 | ||||||||||||

| ALT-5 | MCASP2_AXR7 | ||||||||||||

| ALT-7 | GPIO1_4 | ||||||||||||

| J2.180 | VAR | VAR_D_180 | S | IO | RGMII2_RD2 | SoC | AC21 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_RD2 | ||

| ALT-2 | MCASP2_AXR0 | ||||||||||||

| ALT-3 | PR0_PRU0_GPO4 | ||||||||||||

| ALT-4 | PR0_PRU0_GPI4 | ||||||||||||

| ALT-5 | PR0_UART0_RXD | ||||||||||||

| ALT-7 | GPIO1_5 | ||||||||||||

| ALT-8 | EQEP2_A | ||||||||||||

| J2.182 | VAR | VAR_D_182 | S | IO | RGMII2_RD3 | SoC | AE22 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_RD3 | ||

| ALT-2 | AUDIO_EXT_REFCLK0 | ||||||||||||

| ALT-3 | PR0_PRU0_GPO16 | ||||||||||||

| ALT-4 | PR0_PRU0_GPI16 | ||||||||||||

| ALT-5 | PR0_UART0_TXD | ||||||||||||

| ALT-7 | GPIO1_6 | ||||||||||||

| ALT-8 | EQEP2_B | ||||||||||||

| J2.184 | VAR | VAR_D_184 | S | IO | RGMII2_RXC | SoC | AD23 | VDD_RGMII | VDDSHV2 | ALT-0 | RGMII2_RXC | ||

| ALT-1 | RMII2_REF_CLK | ||||||||||||

| ALT-2 | MCASP2_AXR1 | ||||||||||||

| ALT-3 | PR0_PRU0_GPO1 | ||||||||||||

| ALT-4 | PR0_PRU0_GPI1 | ||||||||||||

| ALT-5 | PR0_ECAP0_SYNC_IN | ||||||||||||

| ALT-7 | GPIO1_2 | ||||||||||||

| J2.186 | AP | USB_A_VBUS | A | I | USB0_VBUS | SoC | AC11 | VDD_3V3 | VDDA_3P3_USB | Buffered, Vth = 3,54 V | |||

| J2.188 | AP | USB_B_VBUS | A | I | USB1_VBUS | SoC | AB10 | VDD_3V3 | VDDA_3P3_USB | Buffered, Vth = 3,54 V | |||

| J2.190 | AP | DGND | G | DGND | |||||||||

| J2.192 | AP | USB_A_ID | S | IO | GPMC0_ADV_ALE# | SoC | L23 | VDD_3V3 | VDDSHV3 | ALT-0 | GPMC0_ADV_ALE# | ||

| ALT-2 | MCASP1_AXR2 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO9 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI9 | ||||||||||||

| ALT-6 | TRC_DATA7 | ||||||||||||

| ALT-7 | GPIO0_32 | ||||||||||||

| J2.194 | AP | USB_B_ID | S | IO | GPMC0_OE_RE# | SoC | L24 | VDD_3V3 | VDDSHV3 | ALT-0 | GPMC0_OE_RE# | ||

| ALT-2 | MCASP1_AXR1 | ||||||||||||

| ALT-4 | PR0_PRU0_GPO10 | ||||||||||||

| ALT-5 | PR0_PRU0_GPI10 | ||||||||||||

| ALT-6 | TRC_DATA8 | ||||||||||||

| ALT-7 | GPIO0_33 | ||||||||||||

| J2.196 | AP | USB_A_N | D | IO | USB0_D_N | SoC | AE11 | VDD_3V3 | VDDA_3P3_USB | ||||

| J2.198 | AP | USB_A_P | D | IO | USB0_D_P | SoC | AD11 | VDD_3V3 | VDDA_3P3_USB | ||||

| J2.200 | AP | USB_B_N | D | IO | USB1_D_N | SoC | AD10 | VDD_3V3 | VDDA_3P3_USB | ||||

| J2.202 | AP | USB_B_P | D | IO | USB1_D_P | SoC | AE9 | VDD_3V3 | VDDA_3P3_USB | ||||

| J2.204 | AP | DGND | G | DGND | |||||||||

Power and reset[edit | edit source]

Power Supply Unit (PSU) and recommended power-up sequence[edit | edit source]

Implementing correct power-up sequence for AM62x SoC processors is not a trivial task because several power rails are involved.

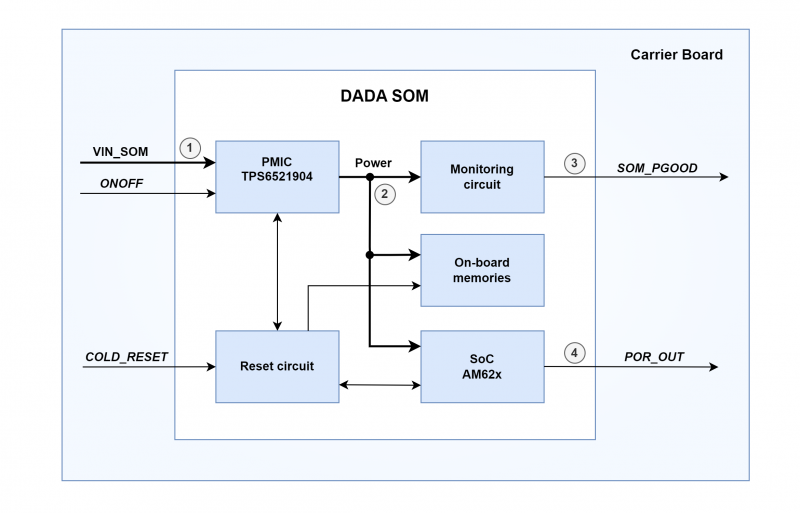

DADA SOM simplifies this task by embedding all the needed circuitry. The following picture shows a simplified block diagram of PSU/voltage monitoring circuitry:

The PSU is composed of two main blocks:

- power management integrated circuit (PMIC)

- additional generic power management circuitry that completes PMIC functionalities

The PSU:

- generates the proper power-up sequence required by the SoC processor and surrounding memories and peripherals

- synchronizes the powering up of carrier board's circuitry to prevent back powering

See the pinout section for more details on the signals.

Power-up sequence[edit | edit source]

The typical power-up sequence is the following:

- VIN_SOM (+3.3V) main power supply rail is powered.

- POR_OUT (active-low) is driven low; PMIC initiates power-up sequence needed by AM62x processor.

- SOM_PGOOD goes up when all SoC, memories, and I/O power rails are ready.

- Finally, the processor is brought out of reset and the POR_OUT signal is released.

For a detailed description of the reset circuit and its signals see the page Reset_scheme_and_control_signals.

Control signals and their purpose[edit | edit source]

SOM_PGOOD[edit | edit source]

SOM_PGOOD is generally used on carrier board to drive loads such as DC/DC enable inputs or switch on/off control signals in order to prevent back power.

Depending on the kind of such loads, SOM_PGOOD might not be able to drive them properly. On DADA SoM this signal is driven by a push-pull output at VIN_SOM (3.3 V) rail, with max 10 mA output current (recommended 1 mA).

On Unica Industrial Dave standard pinout it is a always-present type signal i.e. the pin only covers this functionality on any other Industrial SoM.

ONOFF[edit | edit source]

Long ONOFF signal retention causes the SoM to turn OFF or ON, with a complete power off/on sequence. This is not intended as a low-power mode, since completely turning off the SoM causes the loss of volatile content such as data in RAM.

When the SoM is first powered it turns on without acting on ONOFF signal.

On SoM the signal is pulled-up with 10 kOhm to VIN_SOM (3.3 V).

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

COLD_RESET[edit | edit source]

COLD_RESET is an input signal that cause a SoC cold reset. On SoM the signal is pulled-up with 10 kOhm to VDD_3V3 (3.3 V).

A cold reset of the SoC does not result in a complete power sequence of the SoM.

On Unica Industrial Dave standard pinout it is a always-present type signal i.e. the pin only covers this functionality on any other Industrial SoM.

POR_OUT[edit | edit source]

POR_OUT is an open-drain output (a pull-up on a carrier is required) to be used to reset peripherals on carriers. The signal is released by the SoC when it exits reset (either cold or warm reset).

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

Note on reset signals usage and carrier board PSU[edit | edit source]

In Unica Industrial Dave standard, only SOM_PGOOD and COLD_RESET signals were foreseen as always-present. With only the SOM_PGOOD output signal you need to:

- ensure the carrier PSU activates before the SoM exits reset (for DADA SoM POR_OUT is released about 17 ms after SOM_PGOOD)

- generate a peripheral reset signal on the carrier

It is possible if variable signals are also available:

- with POR_OUT output: reset the peripherals on carrier synchronously with the SoM

- with WARM_RESET input: keep SoM in reset until the carrier PSU is active

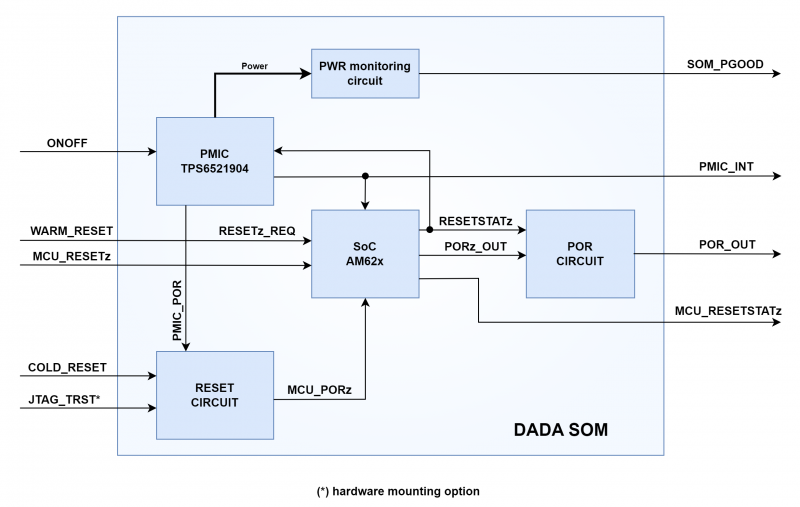

Reset scheme and control signals[edit | edit source]

The AM62x SoC provides several reset signals for its different domains: the following table summarises the TI nomenclature and purpose. Reading "AM62x Processors Technical Reference Manual" [1] is highly recommended.

| SoC signal | SoC domain | Type | Description |

|---|---|---|---|

| MCU_PORz | MCU | Input | MCU Domain cold reset |

| MCU_RESETz | MCU | Input | MCU Domain warm reset |

| RESETz_REQ | Main | Input | Main Domain external warm reset request |

| PORz_OUT | Main | Output | Main Domain POR status output |

| MCU_RESETSTATz | MCU | Output | MCU Domain warm reset status output |

| RESETSTATz | Main | Output | Main Domain warm reset status output |

The following picture instead shows the simplified block diagram of reset scheme and voltage monitoring, referring to the nomenclature of the DADA signals.

The six reset signals of SoC are all usable by the SoM. When designing the SoM pinout, the MCU domain signals were mapped separately, while the Main domain signals were mapped to functions defined in Unica Industrial Dave standard pinout.

See the pinout section for more details on the signals.

Reset signals and their purpose[edit | edit source]

COLD_RESET[edit | edit source]

COLD_RESET is an input signal that cause a SoC cold reset. On SoM the signal is pulled-up with 10 kOhm to VDD_3V3 (3.3 V).

A cold reset of the SoC does not result in a complete power sequence of the SoM.

On Unica Industrial Dave standard pinout it is a always-present type signal i.e. the pin only covers this functionality on any other Industrial SoM.

WARM_RESET[edit | edit source]

WARM_RESET is connected to RESETz_REQ SoC input that starts the main domain warm reset. On SoM the signal is pulled-up with 10 kOhm to VDD_3V3 (3.3 V).

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

MCU_RESETz[edit | edit source]

MCU_RESETz is a SoC input (VDD_3V3) that starts the MCU domain warm reset.

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

POR_OUT[edit | edit source]

POR_OUT is an open-drain output (a pull-up on a carrier is required) to be used to reset peripherals on carriers. The signal is released by the SoC when it exits reset (either cold or warm main domain reset).

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

MCU_RESETSTATz[edit | edit source]

MCU_RESETSTATz is a push-pull (VDD_3V3) SoC output, released by the SoC when it MCU domain exits warm reset.

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

PMIC_INT[edit | edit source]

PMIC_INT is a open-drain PMIC output; on SoM the signal is pulled-up with 10 kOhm to VDD_3V3 (3.3 V).

The signal is asserted low in case of PMIC fault condition.

On Unica Industrial Dave standard pinout it is a always-present type signal i.e. the pin only covers this functionality on any other Industrial SoM.

ONOFF[edit | edit source]

Long ONOFF signal retention causes the SoM to turn OFF or ON, with a complete power off/on sequence. This is not intended as a low-power mode, since completely turning off the SoM causes the loss of volatile content such as data in RAM. When the SoM is first powered it turns on without acting on ONOFF signal.

On SoM the signal is pulled-up with 10 kOhm to VIN_SOM (3.3 V).

On Unica Industrial Dave standard pinout it is a variable type signal i.e. the pin can assume different functions on other Industrial SoMs.

SOM_PGOOD[edit | edit source]

SOM_PGOOD is generally used on carrier board to drive loads such as DC/DC enable inputs or switch on/off control signals in order to prevent back power.

Depending on the kind of such loads, SOM_PGOOD might not be able to drive them properly. On DADA SoM this signal is driven by a push-pull output at VIN_SOM (3.3 V) rail, with max 10 mA output current (recommended 1 mA).

On Unica Industrial Dave standard pinout it is a always-present type signal i.e. the pin only covers this functionality on any other Industrial SoM.

JTAG_TRST[edit | edit source]

This signal is connected to the JTAG cell (see JTAG page). With a hardware variant, it is also possible to force a cold reset of the SoC with this signal.

References[edit | edit source]

[1] TI, AM62x Processors Silicon Revision 1.0, Technical Reference Manual

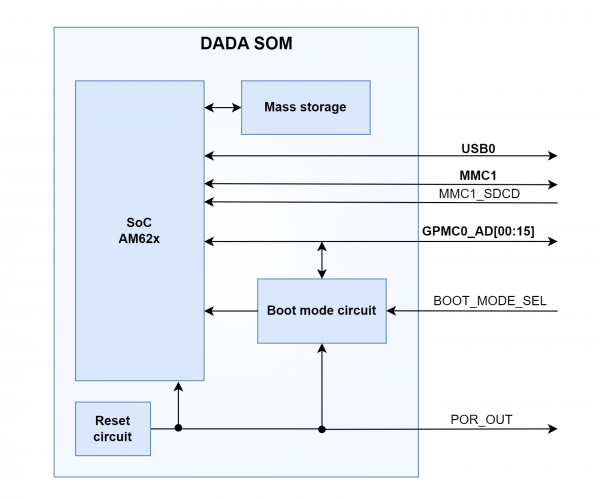

System boot[edit | edit source]

|

This page illustrates the characteristics of the DADA's boot subsystem. Reading of the chapter Initialization of the "AM62x Processors Technical Reference Manual" [1] is highly recommended, though. AM62x SoC features several options in terms of booting. Such options are detailed in that document. |

The boot process begins at Power On Reset (POR) where the hardware reset logic forces the ARM core to begin execution starting from the on-chip boot ROM. The boot ROM:

- determines whether the boot is secure or non-secure

- performs some initialization of the system and clean-ups

- reads the mode pins to determine the primary boot device

- once it is satisfied, it executes the boot code

Boot options[edit | edit source]

The default primary boot device is defined at the factory and identified by the 'Boot Mode' field of the ordering code as follows:

- 0: on board QSPI NOR or MMC1 (uSD) option (SoM code: DSAAxxx0xxxxR)

- 1: on board eMMC or MMC1 (uSD) option (SoM code: DSAAxxx1xxxxR)

For both options an alternative primary boot from SD/MMC card is provided, selectable by driving low the BOOT_MODE_SEL signal: BOOT_MODE_SEL is latched when processor reset is released.

Bootable SD/MMC card connects via the MMC1 bus, mapped on SDIO_A bus referring to Unica Industrial Dave standard pinout.

If primary boot fails, the bootrom goes to the 'USB boot mode' to read the boot image from external USB host, connected to the USB0 bus.

| Ordering code 'Boot Mode' fileld | BOOT_MODE_SEL | Primary boot mode/device | Backup boot mode/device |

|---|---|---|---|

| 0 | 0 | SD/MMC card on MMC1 bus | USB host on USB0 bus |

| 1 | QSPI NOR on OSPI0 bus | ||

| 1 | 0 | SD/MMC card on MMC1 bus | USB host on USB0 bus |

| 1 | eMMC on MMC0 bus |

Other options are available on-demand, however, allowing the implementation of different configurations. DAVE Embedded Systems' team is available for additional information on this matter, please contact sales@dave.eu.

Note on boot signals[edit | edit source]

Bootstrap stage has to be intended as the time elapsing between the release of hardware reset (POR_OUT) and the execution of the first instruction of user code (typically this is the reset vector of U-Boot boot loader). The following figure shows the signals involved in the boot phase.

See the pinout section for more details on the signals.

The following boot signals are latched by the 'boot mode circuit' when processor reset POR_OUT signal is released.

BOOT_MODE_SEL[edit | edit source]

Inside the SOM, BOOT_MODE_SEL signal is pulled-up with 10 kohm.

SD card detect[edit | edit source]

Boot ROM detects SD/MMC card on MMC1 bus: if a card is inserted, ROM will try to boot from it.

MMC1_SDCD signal (named SDIO_A_CD on Unica Industrial Dave standard pinout) is used as card detect signal during bootstrap stage: this signal need to be kept low for boot from SD/MMC card.

Inside the SOM, MMC1_SDCD signal is pulled-up with 10 kohm.

Bootstrap bits[edit | edit source]

Upon exiting the reset the 'boot mode circuit' samples the value of the bootstrap bits, belonging to the GPMC0_AD[0:15] lines:

- to set these bits there are PULL-UP or PULL-DOWN resistors on SoM

- all signals are routed to SoM J1 connector interface, so they can be externally modified by forcing a voltage values

When developing the carrier board, pay attention to the connection of these signals (they have a PD or PU resistance, avoid applying voltages during bootstrap stage).

References[edit | edit source]

[1] TI, AM62x Processors Silicon Revision 1.0, Technical Reference Manual

JTAG[edit | edit source]

JTAG signals are routed to the J1 primary connector of the DADA PCB. These signals output at 3.3 V logic.

For standard operation, the JTAG cell remains in reset: this is ensured by an on SoM pull-down resistor on JTAG_TRSTn signal. To enable a JTAG interface, drive the JTAG_TRSTn signal high.

| Pin | Pin type | UNICA pin name | Notes |

|---|---|---|---|

| J1.56 | Always present | DGND | - |

| J1.52 | Always present | JTAG_TCK | Input CMOS 3.3 V |

| J1.50 | Always present | JTAG_TMS | Input CMOS 3.3 V |

| J1.54 | Always present | JTAG_TDO | Ouput CMOS 3.3 V |

| J1.48 | Always present | JTAG_TDI | Input CMOS 3.3 V |

| J1.46 | Variable | JTAG_TRSTn | Input CMOS 3.3 V with 10K pull-down. |

See the pinout section for more details.

For additional features such as boundary scan, please contact DAVE Embedded Systems' team sales@dave.eu.

Peripherals[edit | edit source]

Peripheral Ethernet[edit | edit source]

The DADA SOM has a 3-port Gigabit Ethernet Switch (CPSW0) subsystem that provides Ethernet packet communication for the device and can be configured as an Ethernet switch.

Description[edit | edit source]

The 3-port CPSW0 subsystem provides the following features:

- Two Ethernet ports (port 1 and 2) with selectable RGMII and RMII interfaces and an internal Communications Port Programming Interface (CPPI) port (port 0)

- Synchronous 10/100/1000 Mbit operation: full duplex mode supported in 10/100/1000 Mbps. Half-duplex mode supported only in 10/100 Mbps modes only

- Flexible logical FIFO-based packet buffer structure

- Eight priority level Quality Of Service (QOS) support (802.1p)

- Support for Audio/Video Bridging (P802.1Qav/D6.0)

- Support for IEEE 1588 Clock Synchronization (2008 Annex D, Annex E and Annex F)

- Timestamp module capable of time stamping external timesync events like Pulse-Per-Second and also generating Pulse-Per-Second outputs

- CPTS module that supports time stamping for IEEE1588 with support for 4 hardware push events and generation of compare output pulses

- Maximum frame size of 2024 bytes

- Management Data Input/Output (MDIO) module for PHY Management with Clause 45 support

- DSCP Priority Mapping (IPv4 and IPv6)

- Energy Efficient Ethernet (EEE) support (802.3az)

- Flow Control Support (802.3x)

- Wire rate switching (802.1d)

- Non-Blocking switch fabric

- Time Sensitive Network Support (IEEE P802.3br Interspersing Express Traffic, IEEE 802.1Qbv Enhancements for Scheduled Traffic)

- Address Lookup Engine (ALE with configurable number of addresses plus VLANs, spanning tree support, MAC authentication 802.1x and blocking, OUI (Vendor ID) host accept/deny feature, VLAN support)

- 802.1Q compliant (Auto add port VLAN for untagged frames on ingress and Auto VLAN removal on egress and auto pad to minimum frame size)

- EtherStats and 802.3Stats Remote Network Monitoring (RMON) statistics gathering (per port statistics)

- Ethernet Mac transmit to Ethernet Mac receive Loopback mode (digital loopback) supported

Peripheral MMC[edit | edit source]

Each MMCSD instance - in the DADA SOM - includes one MMCSD Host Controller. A host controller can support eMMC and/or SD/SDIO. Up to 2 (two) MMCSD ports are available in the DADA SOM.

Description[edit | edit source]

- Each MMCSD module has the following features:

- Advanced DMA

- System Bus Interface:

- 64-bit data width (host interface)

- 64-bit address

- Clock asynchronous to MMCSD clock (MMCi_CLK)

- Configuration Bus Interface:

- 32-bit data width (target interface)

- Linear incrementing addressing mode

- 32-bit aligned accesses only

- MMCSD Host Controller - eMMC interface (see the device-specific AM62x datasheet for supported instances):

- Multi-Media Card Support

- eMMC Electrical Standard 5.1 (JESD84-B51)

- Backward compatible with earlier eMMC standards

- Legacy MMC SDR

- High Speed SDR

- High Speed DDR

- HS200 SDR

- Multi-Media Card Support

- MMCSD Host Controller - SD/SDIO interface (see the device-specific AM62x datasheet for supported instances):

- Secure Digital Card Support

- Backward compatible with earlier SD card specifications

- SD Host Controller Standard Specification 4.10 and SD Physical Layer Specification v3.01, SDIO Specification v3.00

- Default Speed mode

- High Speed mode

- SDR12, SDR25, SDR50, DDR50 (UHS-I 1.8 V)

- Secure Digital Card Support

Peripheral USB[edit | edit source]

The AM62x SoC instantiates two independent instances of a third-party USB subsystem (USB2SS) operating at up to USB2.0 speeds (480Mb/s), either of which can be independently configured to act as a USB Host or a USB Device.

Description[edit | edit source]

The USB 2.0 subsystem (USB2SS) supports the following USB Features:

- Operational modes:

- Supports USB 2.0 Host mode at High-Speed (HS, 480 Mbps), Full-Speed (FS, 12 Mbps), and Low-Speed (LS, 1.5 Mbps)

- Supports USB 2.0 Device mode at High-Speed (HS, 480 Mbps), and Full-Speed (FS, 12 Mbps). Low-Speed is not supported in Device mode

- Supports all modes of transfers - Control, Bulk, Interrupt, and Isochronous

- A DRD (Dual-Role-Device - Host or Device) USB controller with the following features:

- Compatible to the xHCI 1.0 specification in Host mode

- Compatible with the USB 2.0 specification in Device mode

- Supports 15 IN (Receive), 15 OUT (Transmit) endpoints (EPs), and one EP0 endpoint which is bidirectional

- Operation flexibility

- Same programming model for HS, FS, and LS operation

- Each controller instance can provide either USB Host or USB Device functionality

Peripheral Display Subsystem[edit | edit source]

The Display Subsystem (DSS) - in the DADA SOM - is a flexible, multi-pipeline subsystem that supports high-resolution display outputs. Display outputs can connect seamlessly to an Open LVDS Display Interface transmitter (OLDITX), or can directly drive device pads as a Display Parallel Interface (DPI).

Description[edit | edit source]

The Display Subsystem module includes the following features:

- Two display outputs

- up to 24-bit per pixel parallel or embedded sync output

- up to 200MHz pizel clock

- supports

- 1920x1080@60 fps

- 1x 2048x1080 + 1x 1280x720

- RGB/YUV422 modes

- Progressive/interlaced modes

- two display pipelines support 2x Open LVDS Interface 4-data/1clk link (either shared to provide a 4K display or mirroring the same display - independent displays on each OLDI are not supported)

- Two input display processing pipelines

- one video pipeline supporting full RGB and 8/10-bit YUV data formats capable of 0.25x to 16x resizing

- one video_lite pipeline supporting full RGB and 8/10 YUV data formats (no resizing support)

- Two Overlay Managers with multi-layer alpha blending

- One DMA controller capable of supporting up to 2K input source width

- On-the-fly X/Y-axis Flip/Mirror mode support

Peripheral Camera Subsystem[edit | edit source]

The Camera Serial Interface Receiver (CSI_RX_IF) - in the DADA SOM - allows the device to stream video inputs from multiple cameras to internal memory.

Description[edit | edit source]

The CSI_RX_IF module supports the following features:

- Compliant to MIPI CSI v1.3

- supports up to 16 virtual channels per input (partial MIPI CSI v2.0 feature)

- Data rate up to 2.5 Gbps per lane (wire rate)

- Supports 1, 2, 3, or 4 Data Lane connection to DPHY_RX

- Programmable formats including YUV420, YUV422, RGB, Raw, and User Defined (over 25 different formats supported)

- One independent (simultaneous) output stream:

- One (up to 32 Channels) DMA interface through a 128-bit PSI_L connection to DMSS for transfers to memory:

- Byte packed (32x4) format, elastic buffer mode, max rate 1 data cycle every 4 main clocks

- 32 thread ID’s supported (virtual channel & data type combinations); Flexible number of threads (32 Max)

- Virtual channels and data types mapped via mmr to PSI_L thread ID’s

- Internal FF based FIFO; RAM based buffer (2kx128)

- One (up to 32 Channels) DMA interface through a 128-bit PSI_L connection to DMSS for transfers to memory:

- Video inputs come from the DPHY_RX which allows the camera physical port module to grab video streams from external sensor cameras and other CSI2 compliant sources

- Compliant to MIPI D-PHY standard v1.2

- Supports up to 4 data and 1 clock lanes

- Supports up to 2.5 Gbps (with deskew) and 1.5 Gbps (without deskew) per data lane

Peripheral Industrial interfaces[edit | edit source]

The AM62x SoC in the DADA SOM has several industrial interfaces for automotive and industrial applications like Industrial HMI, driver monitoring systems, EV charging stations.

Description[edit | edit source]

The following industrial interfaces are available:

- 3x enhanced PWM modules (ePWM)

- 3x enhanced Quadrature Encoder Pulse modules (eQEP)

- 3x enhanced Capture modules (ECAP)

- Timer modules

Enhanced Pulse Width Modulation[edit | edit source]

The Enhanced Pulse Width Modulation (ePWM) interface (DSMIF) is able to generate complex pulse width waveforms with minimal CPU overhead or intervention.

The three ePWM modules support the following features:

- Dedicated 16-bit time-base counter with period and frequency control

- Two PWM outputs (EPWMxA and EPWMxB) that can be used as two independent PWM outputs with single-edge operation, two independent PWM outputs with dual-edge symmetric operation or one independent PWM output with dual-edge asymmetric operation

- Asynchronous override control of PWM signals through software

- Programmable phase-control support for lag or lead operation relative to other EPWM modules

- Hardware-locked (synchronized) phase relationship on a cycle-by-cycle basis

- Dead-band generation with independent rising and falling edge delay control

- Programmable trip zone allocation of both cycle-by-cycle trip and one-shot trip on fault conditions

- A trip condition can force either high, low, or high-impedance state logic levels at PWM outputs

- Allows events to trigger both CPU interrupts and ADC start of conversions

- PWM chopping by a high-frequency carrier signal, useful for pulse transformer gate drives

Enhanced Quadrature Encoder Pulse modules[edit | edit source]

The Enhanced Quadrature Encoder Pulse (EQEP) peripheral is used for direct interface with a linear or rotary incremental encoder to get position, direction and speed information from a rotating machine for use in high performance motion and position control system.

The three eQEP include the following features:

- Input synchronization

- Three stage/six stage digital noise filter

- Quadrature decoder unit

- Position counter and control unit for position measurement

- Quadrature edge capture unit for low-speed measurement

- Unit time base for speed and frequency measurement

- Watchdog timer for detecting stalls

- EQEP inputs (A/B/INDEX and STROBE) are available at chip level

- EQEP phase error output is also available

Enhanced Capture modules[edit | edit source]

The Enhanced Capture (ECAP) module can be used for:

- Sample rate measurements of audio inputs

- Speed measurements of rotating machinery (for example, toothed sprockets sensed via Hall sensors)

- Elapsed time measurements between position sensor pulses

- Period and duty cycle measurements of pulse train signals

- Decoding current or voltage amplitude derived from duty cycle encoded current/voltage sensors

The ECAP module includes the following features:

- 32-bit time base counter

- 4 × 32 bits event time-stamp capture registers (ECAP0_CAP1 through ECAP0_CAP4)

- 4-stage sequencer (Mod4 counter), synchronized to external events (ECAPx pin edges)